In industrial applications, the efficiency of fluid power systems hinges significantly on the components used, with Pressure Directional Valves being pivotal in regulating fluid flow and pressure. According to a report by MarketsandMarkets, the global market for pressure control equipment, including directional valves, is projected to reach $15.17 billion by 2025, growing at a CAGR of 5.2%. This surge underscores the increasing reliance on advanced hydraulic technologies to optimize performance and enhance safety in operations.

As industries seek to improve productivity and reduce downtime, understanding the functionality of Pressure Directional Valves becomes essential. These valves not only manage flow direction but also play a crucial role in maintaining system pressure, ensuring that equipment operates efficiently within its designed parameters.

In this blog, we will explore the workings of Pressure Directional Valves, their applications, and best practices for their implementation in various industrial settings.

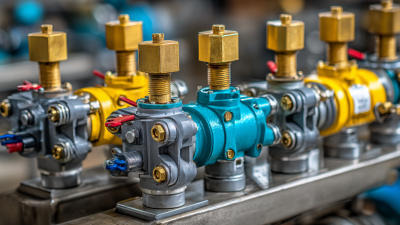

Pressure directional valves are crucial components in industrial fluid power systems, playing a vital role in controlling the flow and pressure of fluids. These valves are designed to manage the direction of fluid flow based on the operational requirements, ensuring that the hydraulic or pneumatic systems function efficiently and safely. Key components of pressure directional valves include the actuator, valve body, and spring assembly. The actuator is responsible for responding to control signals, while the valve body contains the internal pathways that direct fluid flow. The spring assembly plays a critical role in returning the valve to its default position when the actuator is not engaged.

Another important aspect of pressure directional valves is the use of spool profiles, which are specifically designed to meet different operational needs. Variations in spool design can impact the flow rate, pressure maintenance, and overall responsiveness of the system. Additionally, seals and auxiliary components such as filters and mounted sensors help ensure that the valves operate with minimal leakage and maximum efficiency. Understanding these components and their interrelations is essential for the effective design and maintenance of industrial systems, enabling engineers to optimize performance and reliability in various applications.

| Component | Function | Typical Applications | Operating Pressure Range (bar) | Control Type |

|---|---|---|---|---|

| Spool | Directs flow to appropriate output ports | Hydraulic presses, automation systems | 10-350 | Electric, pneumatic |

| Actuator | Moves the spool to allocate flow | Machinery operation, robotics | 10-200 | Hydraulic, mechanical |

| Spring | Holds spool in default position | Safety valves, fail-safe systems | -1 to 100 | N/A |

| Body | Houses all components and directs flow | General industrial uses, fluid control | 10-400 | N/A |

| Ports | Connects to hydraulic lines | Fluid transmission systems | Varies by application | N/A |

Pressure directional valves play a crucial role in managing fluid flow within industrial systems. Understanding the different types of these valves is essential for optimizing performance and efficiency in various applications. Common types include pressure relief valves, which prevent systems from exceeding pressure limits, and pressure sequence valves, which manage the sequence of operations in hydraulic systems. Each type serves a unique function that enhances safety and reliability in machinery operations.

In addition to these, proportional pressure control valves allow for precise pressure regulation, making them ideal for applications requiring fine control, such as robotics and automated systems. Pneumatic directional valves, on the other hand, are vital in controlling air-powered machinery, ensuring that equipment operates smoothly and effectively. By selecting the appropriate type of pressure directional valve, industrial operators can enhance system functionality and extend the lifespan of their equipment. Understanding these types and their specific applications can lead to improved design and maintenance strategies in any industrial setup.

In industrial applications, pressure directional valves play a crucial role in controlling fluid flow and maintaining system efficiency. To ensure optimal functionality, it is essential to assess various performance criteria. One of the primary factors includes response time, which determines how quickly the valve can redirect fluid under varying pressure conditions. A timely response is especially vital in processes where rapid changes can lead to equipment damage or operational inefficiencies.

Another key criterion is the valve's leakage rate. An optimal direction valve should minimize leakage to maintain system integrity and reduce fluid loss. This is particularly important in sectors like hydraulics and pneumatics, where fluid conservation translates to cost savings and environmental benefits. Additionally, durability and material compatibility are critical, as these factors influence the valve’s lifespan and reliability in challenging industrial environments. By thoroughly evaluating these performance criteria, organizations can select pressure directional valves that not only meet their operational needs but also enhance overall productivity.

Pressure directional valves play a crucial role in the efficient functioning of various industrial applications. However, like any mechanical component, they are prone to issues that can impact performance. Common problems include leakage, sticking, and failure to open or close properly. These issues can arise from wear and tear, dirt accumulation, or improper installation. To prevent such complications, regular inspections are essential. Identifying early signs of malfunction can save time and reduce long-term repair costs.

Maintenance practices are vital to ensuring the longevity and reliability of pressure directional valves. Implementing a routine maintenance schedule that includes cleaning, lubrication, and functional testing can significantly enhance valve performance. It’s important to address any leaks immediately and to replace worn seals and components to avoid further damage. Additionally, staying informed about the operating environment and conditions can help mitigate risks. By following these best practices, industries can ensure their pressure directional valves continue to operate optimally, supporting uninterrupted service and efficiency in industrial operations.

Pressure directional valves play a crucial role in enhancing the efficiency and safety of industrial systems. By controlling the flow of hydraulic fluids, these valves ensure that the machinery operates smoothly, reducing the risk of pressure drops or surges that can lead to equipment damage. In high-pressure environments, efficient valve operation can prevent costly downtime and extend the lifespan of hydraulic systems, making their functionality essential for reliability in production processes.

Tips: Regular maintenance and timely inspection of pressure directional valves can significantly boost overall system performance. Operators should keep an eye on pressure fluctuations and listen for any unusual sounds that may indicate valve malfunctions. Additionally, always ensure that valves are properly calibrated to match the specific requirements of the system they serve.

Furthermore, the integration of pressure directional valves into safety protocols cannot be overstated. These valves not only aid in controlling the flow but also in executing emergency shutdowns when necessary, thereby safeguarding personnel and equipment. In operations where precision is paramount, the right selection and placement of these valves contribute directly to operational safety and efficiency.

Tips: When selecting pressure directional valves, consider factors such as flow rate, pressure rating, and the compatibility of materials with the working fluid. Consulting with a hydraulic specialist can help ensure that you choose valves that align with your specific application needs.