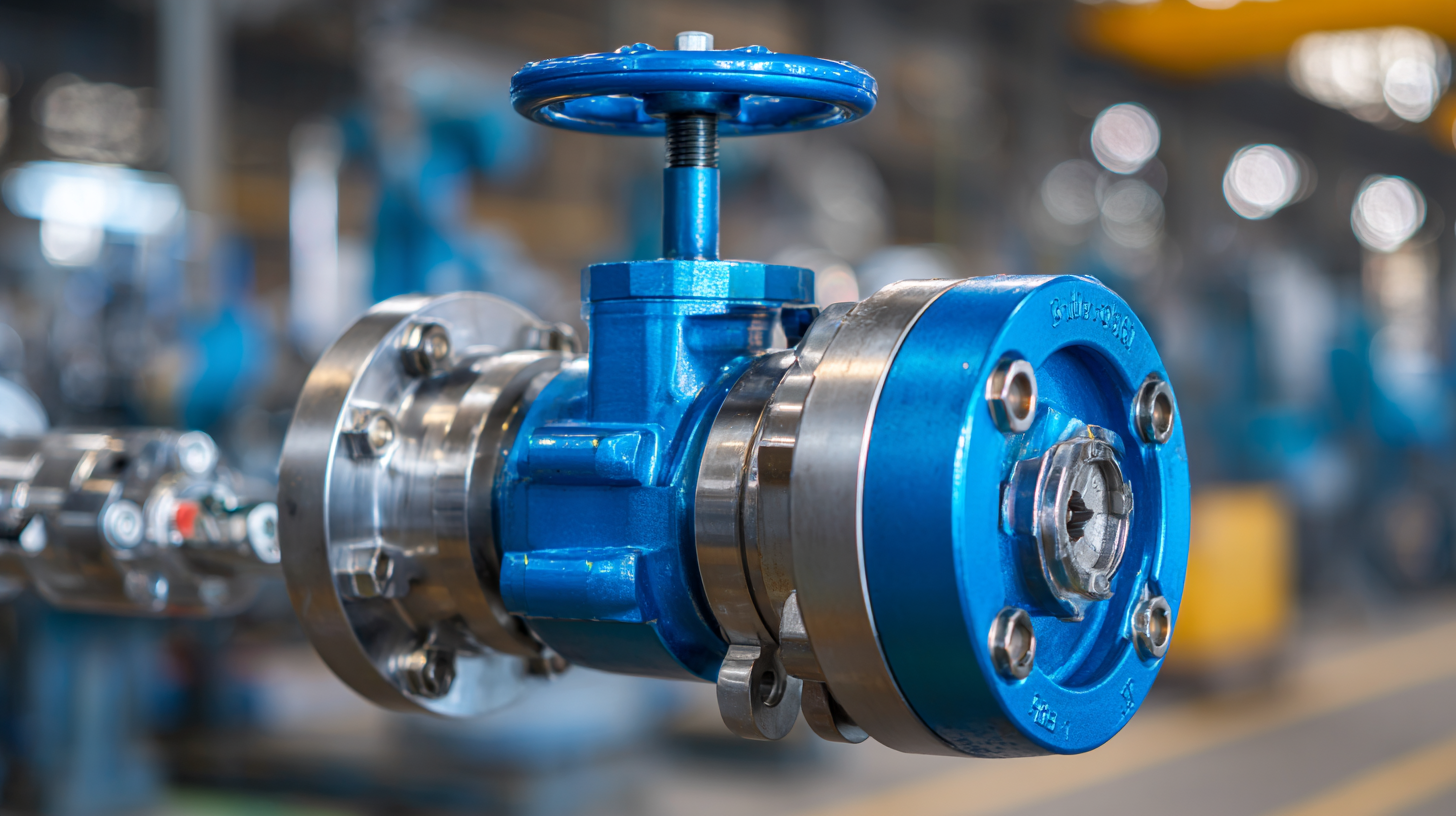

In the rapidly evolving landscape of global trade, the demand for high-quality components such as the Manual Check Valve has surged, underscoring their critical role in various industrial applications. According to a recent report by MarketsandMarkets, the global valve market is expected to reach USD 86.7 billion by 2025, with manual check valves gaining notable traction due to their reliability and efficiency in ensuring unidirectional flow and preventing backflow in fluid systems. As China solidifies its position as a leading manufacturer, leveraging innovative technologies and stringent quality controls, the country is poised to meet this growing demand. This blog will explore how China’s best manual check valve manufacturers are not only enhancing operational excellence but also setting new benchmarks in quality and performance, ultimately unlocking opportunities for businesses around the globe.

The rising demand for manual check valves in global trade is a testament to the evolving landscape of industrial applications. As international trade expands, especially with the surge in bulk cargo transportation via maritime routes, the need for reliable and efficient flow control solutions has never been greater. Manual check valves play a crucial role in ensuring the seamless operation of various systems, preventing backflow and maintaining pressure stability in pipelines used for shipping and marine projects.

China's leadership in the manufacturing of manual check valves positions it well to meet this growing demand. With rigorous quality standards and a commitment to innovation, Chinese manufacturers are not only enhancing the performance of these vital components but also contributing to the overall efficiency of global trade operations. As industries such as HVAC and marine transport continue to grow, the reliance on exceptional manual check valves becomes imperative, ensuring safe and efficient operations across different sectors worldwide.

China has firmly established itself as a cornerstone of global trade, particularly in the manufacturing of high-quality manual check valves. According to a recent report by the International Trade Administration, China accounted for approximately 30% of the world's total valve production in 2022, highlighting its dominance in this sector. This figure underscores not only quantity but also the rigorous standards that Chinese manufacturers adhere to, which often exceed international specifications.

The reputation for quality and reliability in Chinese manufacturing is further evidenced by the implementation of advanced quality management systems, such as ISO 9001 certifications. A significant 70% of Chinese valve manufacturers are certified under this standard, ensuring consistent product performance and safety. As industries globally increasingly prioritize durability and efficiency, the reliability of Chinese-made manual check valves has made them preferable choices for various applications, from oil and gas to water and wastewater management. This commitment to quality positions China as a leader in setting manufacturing benchmarks worldwide.

The global landscape of manual check valve manufacturing is undergoing a remarkable transformation, driven by innovative technologies introduced by leading manufacturers in China. These advancements not only enhance the operational efficiency of valves but also position them as vital components in a variety of sectors, including automotive and industrial applications. As the demand for reliable fluid control systems grows, manufacturers are leveraging cutting-edge production techniques and materials to improve performance and durability.

In particular, the integration of smart technologies and automation into the production process has revolutionized traditional manufacturing practices. This shift enables manufacturers to maintain high-quality standards while significantly increasing production capacity. For instance, the adoption of IoT and AI applications in manufacturing processes has streamlined operations, reduced human error, and optimized resource allocation. As a result, companies can meet the rising market demand for manual check valves, ensuring that they remain competitive and responsive to consumer needs in an ever-evolving trade environment.

In the realm of global trade, the manufacturing of manual check valves in China stands out not only for its scale but also for its emphasis on stringent quality control measures. According to a report by the International Trade Administration, China's valve manufacturing industry is estimated to reach a market value of USD 24 billion by 2025, driven largely by the increasing demand for high-quality products across various sectors, including oil and gas, water distribution, and HVAC systems. This boom underscores the essential role of quality control in ensuring that these critical components meet international standards.

Quality control in China's check valve manufacturing process involves several stages, from raw material selection to final product testing. Advanced techniques such as Six Sigma and Total Quality Management (TQM) are being adopted to minimize defects and enhance product reliability. A study by ResearchAndMarkets noted that implementing robust quality control processes can reduce production costs by up to 30% while increasing customer satisfaction. Such measures ensure that manufacturers not only meet the specifications laid out by international standards like ISO 9001 but also foster a reputation for excellence in the competitive global marketplace.

| Dimension | Specification | Quality Control Process | Inspection Method | Compliance Standard |

|---|---|---|---|---|

| Size | 1/2" to 12" | Incoming Material Inspection | Visual and Dimensional Check | ISO 9001 |

| Body Material | Cast Iron, Stainless Steel | In-Process Quality Checks | Pressure Testing | API 598 |

| End Connection | Flanged, Threaded | Final Product Testing | Functional Testing | ASTM A126 |

| Pressure Rating | Class 150 to Class 300 | Documented Procedures | Dimensional Verification | EN 12266 |

| Application | Water, Oil, Gas | Traceability of Materials | Leak Testing | NADCAP |

In recent years, China’s manual check valve industry has emerged as a leader in integrating sustainable practices into its manufacturing processes. The focus on eco-friendly approaches not only enhances product quality but also minimizes the environmental impact of valve production. Manufacturers are increasingly adopting techniques that reduce waste, conserve water, and use less energy, all while maintaining high standards for safety and durability. By leveraging innovative technologies, companies are ensuring that their processes are as green as possible, setting an example for global trade.

**Tip:** To further support sustainable practices in manufacturing, consider sourcing from suppliers who commit to energy-efficient technologies and use recycled materials in their products. This not only reduces the carbon footprint but also promotes a circular economy.

Additionally, the adoption of eco-friendly materials in the production of manual check valves is paving the way for a more sustainable future. Many manufacturers are experimenting with biodegradable or less harmful substances that still meet performance standards. This shift not only helps in reducing waste but also aligns with global efforts toward more responsible resource management.

**Tip:** When evaluating suppliers, ask about their environmental policies and practices. Compliance with international environmental standards can be a strong indicator of a manufacturer’s commitment to sustainability.

This chart showcases the annual production volumes of manual check valves in China over the past five years (2019-2023) along with their corresponding sustainable practices adopted by manufacturers.