In the rapidly evolving landscape of industrial automation, Directional Control Valves play a pivotal role in enhancing operational efficiency and process reliability. According to a recent market research report by Mordor Intelligence, the global directional control valve market is projected to reach $9.32 billion by 2025, growing at a CAGR of 4.8% during the forecast period. This growth is spurred by increasing demand for automation in manufacturing sectors and the adoption of advanced fluid control systems. As industries strive for greater productivity and reduced operational costs, the innovative designs and advanced technologies incorporated in modern directional control valves are set to address these challenges.

This blog will explore the future trends and top strategies for the optimization of directional control valves, highlighting their crucial role in shaping the industrial automation landscape.

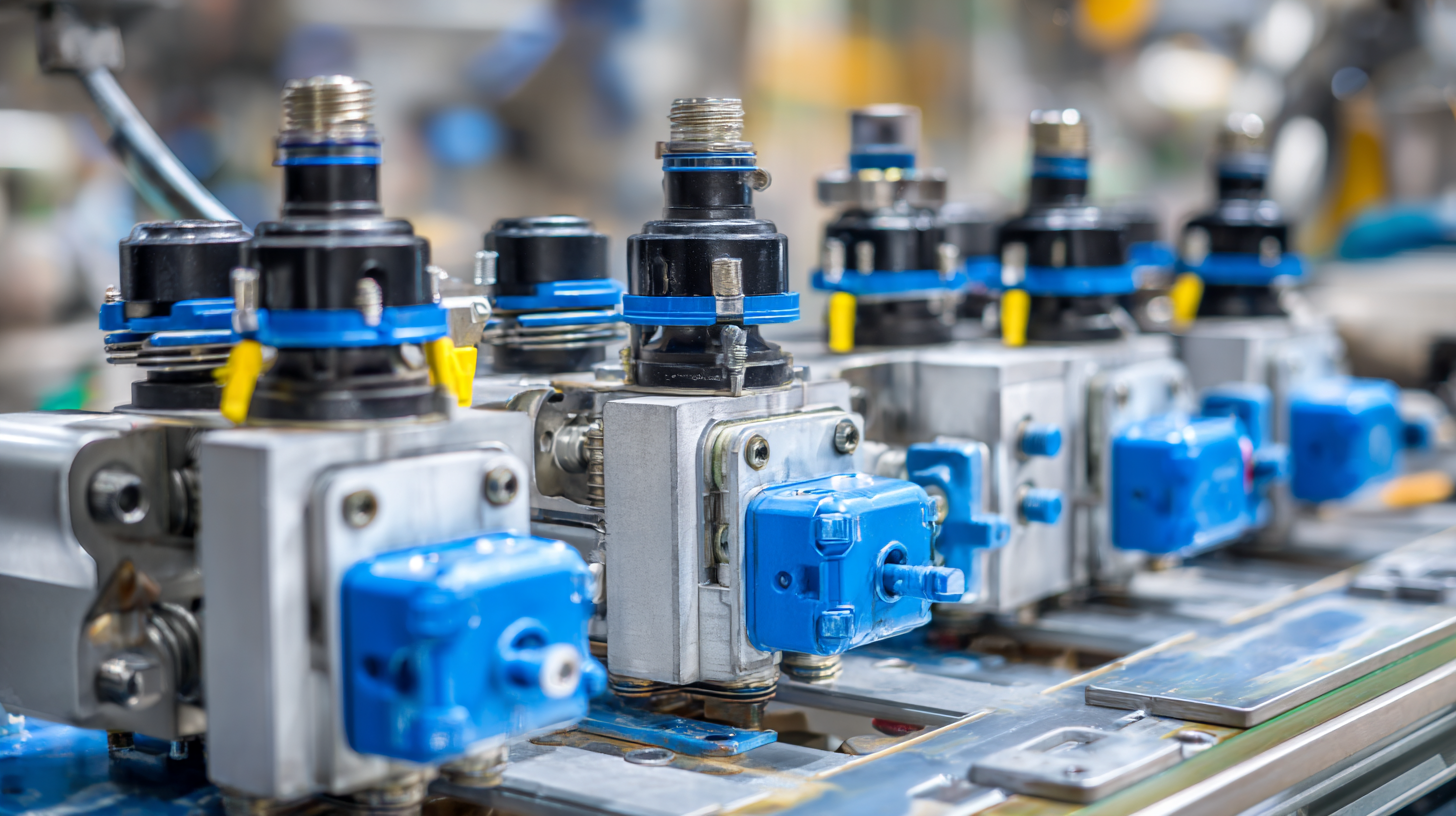

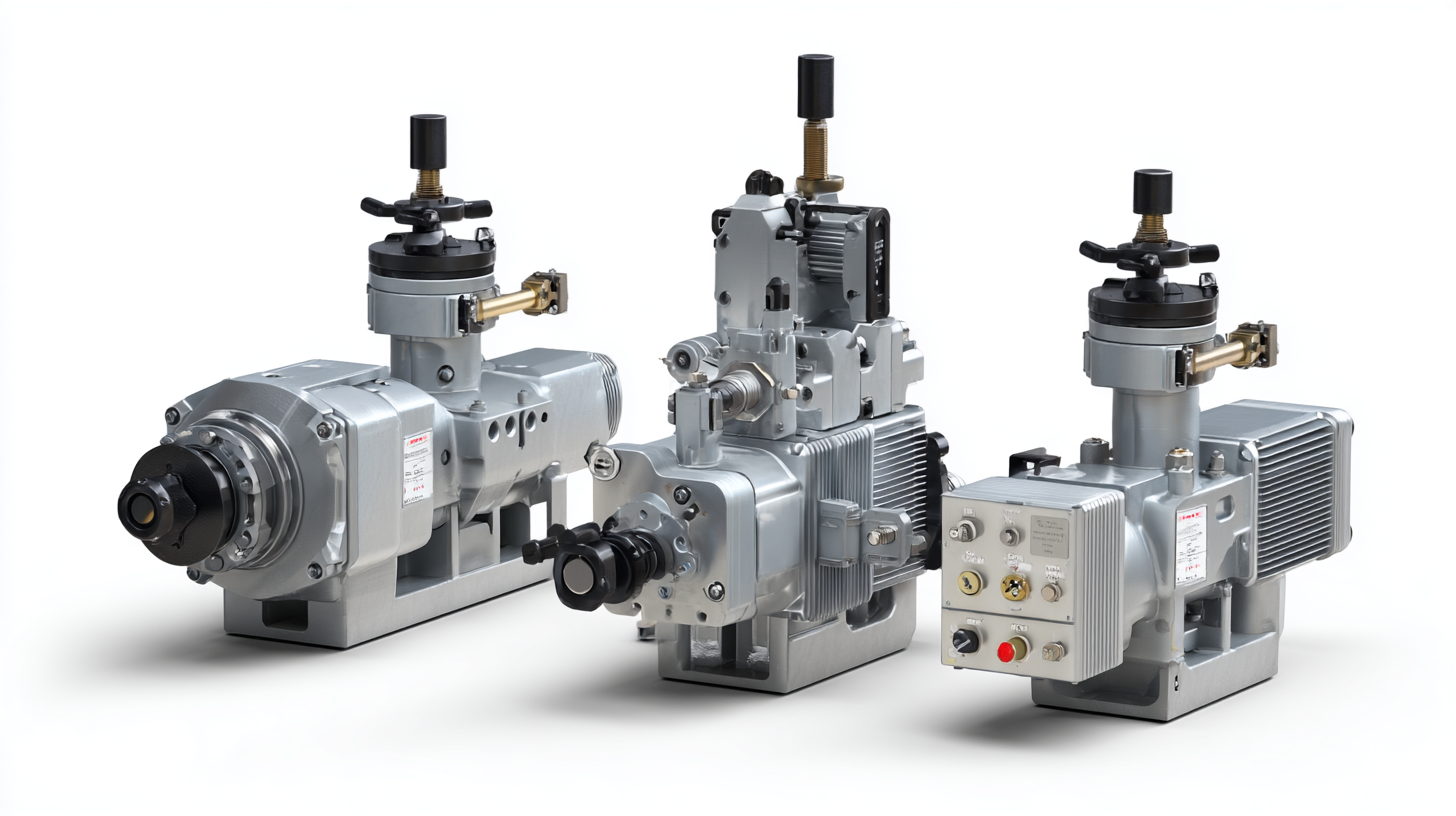

Directional control valves play a pivotal role in the realm of industrial automation, significantly enhancing operational efficiency across diverse applications. Their primary function is to direct hydraulic fluid flow to various parts of a system, allowing for precise control of machinery and processes. In modern engineering contexts, key features such as improved sealing mechanisms, connectivity with IoT systems, and the ability to integrate seamlessly with electric vehicle technologies are becoming vital. These advancements not only boost performance but also contribute to energy savings and streamlined operations.

Tips: When selecting directional control valves, prioritize models that incorporate advanced sealing structures to minimize leakage and enhance durability. Consider how IoT capabilities can integrate with your existing systems, enabling real-time monitoring and remote control to optimize performance. Finally, assess the compatibility of valves with your current hydraulic systems to ensure smooth integration, particularly if you are transitioning to more electrically driven solutions.

As industries move toward greater automation, investing in the latest directional control valve technology can lead to significant improvements in efficiency and productivity, positioning companies to better meet emerging challenges in manufacturing and logistics.

| Feature | Description | Application | Efficiency Impact |

|---|---|---|---|

| High Response Time | Allows for rapid position adjustments to ensure system responsiveness. | Robotic arms and automated machinery | Increases system throughput and reduces cycle time. |

| Energy Efficiency | Minimizes energy consumption during operation checks. | Manufacturing process lines | Lowers operational costs and improves sustainability. |

| Compact Design | Space-saving designs suitable for tight installation areas. | Modular machinery and small-scale equipment | Maximizes available space without compromising performance. |

| Smart Connectivity | Internet of Things (IoT) compatibility for real-time data access. | Industrial automation and control systems | Improved monitoring and predictive maintenance capabilities. |

| Durability | Resistant to harsh environments and extreme temperatures. | Heavy machinery and outdoor applications | Reduces downtime and maintenance costs. |

Directional control valves are integral components in industrial automation, providing precise control of fluid flow and pressure in various applications. The efficiency of these valves can significantly impact overall system performance. For instance, according to a recent market research report, the global directional control valve market is projected to reach $8.3 billion by 2026, growing at a CAGR of 6.2%. This growth underscores the increasing importance of selecting the right valve types for optimal efficiency in production lines.

Directional control valves are integral components in industrial automation, providing precise control of fluid flow and pressure in various applications. The efficiency of these valves can significantly impact overall system performance. For instance, according to a recent market research report, the global directional control valve market is projected to reach $8.3 billion by 2026, growing at a CAGR of 6.2%. This growth underscores the increasing importance of selecting the right valve types for optimal efficiency in production lines.

There are several types of directional control valves – including spool valves, poppet valves, and rotary valves – each offering distinct advantages and efficiencies. Spool valves, for example, are favored in hydraulic systems for their robustness and reliability, often achieving efficiency rates of up to 90%. In contrast, poppet valves are typically used in pneumatic applications, where their quick responsiveness can enhance system throughput. Understanding these differences can aid manufacturers in minimizing energy consumption while maximizing productivity.

Tip: Regular maintenance and monitoring of directional control valves can lead to significant performance improvements. Implementing predictive maintenance strategies can reduce downtime by 20-30%, ensuring that your valves operate at peak efficiency and reliability.

The future of directional control valves is being shaped by remarkable innovations that enhance both industrial automation and efficiency. According to a recent report by the Research and Markets, the global market for directional control valves is projected to reach $4.28 billion by 2025, driven by increasing demand across industries for advanced automation solutions. These valves, crucial for controlling the flow of fluids in pneumatic and hydraulic systems, are becoming smarter and more efficient, integrating IoT technology to provide real-time monitoring and feedback.

As manufacturers strive for operational excellence, adopting valves with advanced features such as proportional control and intelligent diagnostics will be key. For example, using valves that can adapt flow rates dynamically based on system demands reduces wasted energy and enhances overall system responsiveness. **Tip:** Look for directional control valves equipped with smart sensors and predictive maintenance capabilities to minimize downtime and extend equipment life.

Moreover, the rise of eco-friendly technologies brings about new designs focused on sustainability. A study by Deloitte highlights that industrial sectors adopting greener technologies could save up to 25% in energy costs. **Tip:** Evaluate directional control valves made from recyclable materials or those designed to operate with environmentally friendly hydraulic fluids to align with sustainability goals while maintaining high performance.

This chart illustrates the anticipated growth and efficiency improvements in various applications of directional control valves over the next five years. The data reflects market segmentation across different industries including automotive, manufacturing, and energy sectors.

Directional control valves play a crucial role in enhancing automation processes within various industrial sectors. These valves are integral to hydraulic systems, controlling the flow and direction of hydraulic fluid, which in turn influences the efficiency and responsiveness of automated equipment. According to a recent industry report by MarketsandMarkets, the global market for directional control valves is projected to reach $7.1 billion by 2025, growing at a CAGR of 5.4%, highlighting the increasing reliance on automation across industries such as manufacturing, automotive, and pharmaceuticals.

Implementing advanced directional control valves can significantly improve operational efficiency. For instance, proportional valves allow for precise control of actuator movement, which leads to better position accuracy and reduced cycle times. Companies that have adopted such technology report a decrease in energy consumption by up to 30%, highlighting the economic advantages of investing in high-quality directional control valves.

Tip: To maximize the benefits of directional control valves, regularly monitor their performance and consider integrating smart sensors for real-time data collection. Ensuring that these valves are compatible with the latest automation technologies can further enhance system integration and operational efficacy.

The implementation of advanced directional control valves in industrial automation presents several challenges that organizations must navigate to enhance efficiency. One of the primary hurdles is the integration of these valves within existing systems. Many facilities still rely on outdated technology, making it difficult to incorporate newer, more efficient valves without significant modifications. This can lead to increased downtime during installation and higher costs as businesses weigh the benefits against their current infrastructure.

Another challenge lies in the complexity of the control systems associated with modern directional control valves. As automation becomes more sophisticated, so too does the need for precise control and monitoring. This necessitates a workforce skilled in both the operation and maintenance of advanced systems. Companies must invest in training programs and resources to equip their employees with the necessary knowledge to manage these advanced technologies effectively. Additionally, there is a push for standardized protocols that can facilitate easier integration and troubleshooting of these valves across various platforms, ultimately supporting smoother transitions in the industry's shift towards automation.