As the automotive industry continues to evolve, understanding the complexities of auto parts has become crucial for vehicle performance and safety. Among these components, the Auto Parts Hydraulic Valve plays a significant role in controlling fluid flow within various systems, impacting everything from braking to steering. According to a recent report from the Automotive Parts Manufacturers Association, the demand for hydraulic valves in vehicles is expected to grow by 5% annually through 2025. This trend reflects not only the increasing importance of efficient hydraulic systems in modern vehicles but also the need for consumers to choose the right parts to ensure optimal performance.

In this blog, we will delve into the various types of hydraulic valves available in the market, comparing their features, benefits, and applications to help you find the best option that meets your vehicle's specific needs.

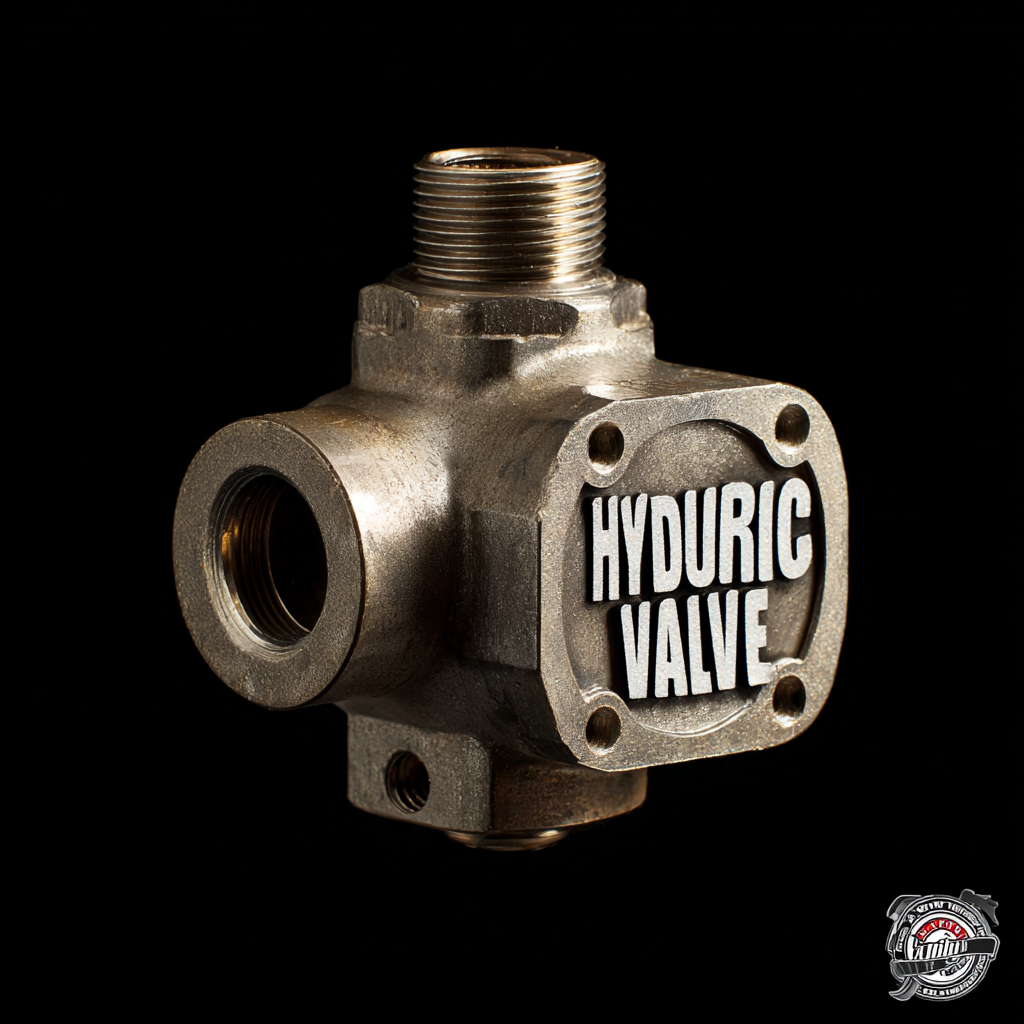

Hydraulic valves play a crucial role in the operation of various vehicle systems, serving as the command center for fluid dynamics within hydraulic circuits. These components control the flow and pressure of hydraulic fluid, enabling systems like steering, brakes, and suspension to function effectively. By modulating fluid movement, hydraulic valves ensure that power is transferred seamlessly, providing optimal performance while enhancing safety and maneuverability.

Hydraulic valves play a crucial role in the operation of various vehicle systems, serving as the command center for fluid dynamics within hydraulic circuits. These components control the flow and pressure of hydraulic fluid, enabling systems like steering, brakes, and suspension to function effectively. By modulating fluid movement, hydraulic valves ensure that power is transferred seamlessly, providing optimal performance while enhancing safety and maneuverability.

In vehicles, the essential functions of hydraulic valves include directing the fluid to specific areas, maintaining pressure, and providing safety relief to prevent system overload. For instance, in hydraulic brake systems, valves regulate the pressure applied to the brake lines, ensuring that stopping power is both efficient and responsive. Similarly, in power steering systems, hydraulic valves adjust the flow of fluid based on steering input, facilitating smoother turns and improved handling. Given their central role, choosing the right hydraulic valves that meet the specific requirements of your vehicle is vital to maintaining its performance and durability.

When it comes to hydraulic systems, selecting the right type of hydraulic valve is crucial for ensuring optimal performance in various applications. Hydraulic valves serve as the control points regulating the flow and direction of hydraulic fluid, making them essential in sectors like transportation, heavy industry, and robotics. Each type of valve—such as gate valves, globe valves, and more specialized options like Tesla valves—offers unique characteristics suited for specific operational requirements.

With rapid advancements in hydraulic valve technology, users face a plethora of choices tailored to their applications. For instance, automated valves are increasingly being favored for their convenience and efficiency, allowing for real-time adjustments and monitoring. Moreover, the integration of sensor technologies into hydraulic valves helps assess performance metrics, enabling users to overcome challenges associated with hydraulic fluid dynamics. Understanding these various types of hydraulic valves and their corresponding applications empowers users to make informed decisions, maximizing the functionality and safety of their hydraulic systems.

| Type of Hydraulic Valve | Best Applications | Flow Capacity (L/min) | Pressure Rating (Bar) | Typical Usage |

|---|---|---|---|---|

| Directional Control Valve | Excavators, Loaders | 30-150 | 250 | Control movement of hydraulic actuators |

| Pressure Relief Valve | Compressors, Hydraulic Pumps | - | 200 | Prevent system overpressure |

| Flow Control Valve | Material Handling, Agricultural Equipment | 10-100 | 150 | Regulate flow rate in hydraulic circuits |

| Check Valve | Cranes, Hydraulics Systems | - | 100 | Prevent backflow in hydraulic lines |

| Solenoid Valve | Automated Machinery, Robotics | 5-50 | 120 | Remote control hydraulics in automation |

When selecting auto parts, particularly hydraulic valves, it's essential to consider several key factors that influence compatibility and performance. A recent market analysis highlights the automotive aftermarket's projected growth, estimating the market to reach approximately $33.8 billion by 2030, with a compound annual growth rate of 4.0% from 2024 to 2030. This growth reflects the increasing consumer awareness of quality replacement parts, driving demand for components that not only fit but also enhance vehicle reliability.

Additionally, the specific application of the components plays a critical role in the decision-making process. For instance, different types of hydraulic valves are designed for various automotive functions, such as transmission control or steering assist. It is crucial to choose parts derived from reputable manufacturers known for their durability and performance under varying conditions. Furthermore, with the rising trend of online purchasing within the aftermarket, where the e-commerce automotive aftermarket in the Asia-Pacific region surpassed $10 billion in 2019, consumers are increasingly leveraging technology to find the best deals on vital components for their vehicles. This shift emphasizes the importance of sourcing reliable parts to ensure safety and efficiency on the road.

Installing hydraulic valves in your vehicle can significantly enhance performance and control. Before you start, ensure you have all the necessary tools, including wrenches, screwdrivers, and safety gear. Begin by identifying the type of hydraulic valve that suits your vehicle's needs, whether it's for a specific application like braking or steering.

**Tips:** Always consult your vehicle's manual to understand the optimal specifications for hydraulic valves. This will help prevent any compatibility issues that could arise during installation.

When you're ready to install, disconnect the battery to ensure safety. Remove the old valve carefully, taking note of the connections and placement. This is crucial for a successful new installation. Once the new valve is in place, reattach all connections and double-check for any leaks before powering the vehicle back on.

**Tips:** Using thread sealant on connections can help prevent leaks and ensure a secure fit. After installation, test the hydraulic system under various conditions to confirm that everything is functioning correctly.

Hydraulic valves play a critical role in the functioning of various vehicle systems, controlling the flow of hydraulic fluid to ensure optimal performance. However, they can develop problems that may lead to significant issues in vehicle operation. Common hydraulic valve problems include leaks, sticking valves, and erratic pressure. Identifying these issues early can save you time and money in repairs, as well as help maintain your vehicle’s efficiency.

To troubleshoot hydraulic valve problems, it’s essential to perform regular inspections. Start by checking for any visible leaks around the valve area, which could indicate a failing seal or gasket. Next, test the valve’s responsiveness by manually operating it, ensuring it moves freely without any sticking. If you notice fluctuations in pressure or performance, it may suggest a blockage or damage within the valve or the hydraulic system. Addressing these issues promptly can restore functionality and prevent further complications, ensuring your vehicle runs smoothly and reliably.