The Difference Between M4/M5 Pilot Relief Valves: Can They Be Used Interchangeably?

When it comes to Hydraulic Systems, safety and efficiency are paramount. One of the most essential components that ensure smooth, controlled operation is the pilot relief valve. These devices are used to control the pressure within a hydraulic circuit, preventing system overloads and protecting equipment from potential damage. Among the various types of pilot relief valves, the M4 and M5 variants are widely used in industrial applications. But can these valves be used interchangeably in different systems?

In this article, we will explore the critical differences between M4 and M5 pilot relief valves, their functions, and why it's essential to understand their specific applications to ensure the longevity and efficiency of your hydraulic systems.

The Risk of Incorrect Pressure Setting of the Main Relief Valve in Hitachi Excavators EX200-5: A Critical Issue for Operators

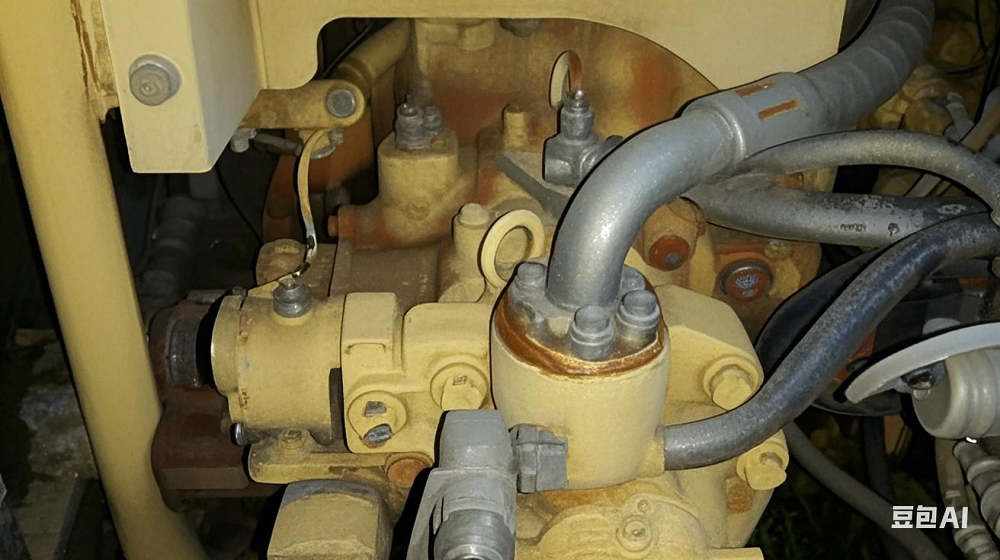

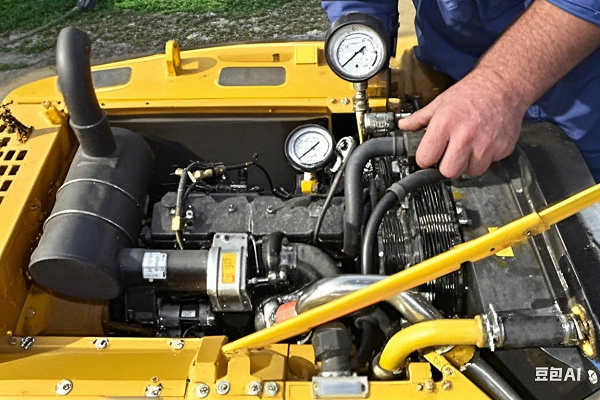

In the world of heavy machinery, precision and maintenance are key factors in ensuring the safety and longevity of equipment. Excavators like the Hitachi EX200-5 are vital tools for construction, mining, and other industrial projects, delivering power and versatility for heavy-duty tasks. However, just as with any machine, even small issues can lead to significant risks. One such issue is the incorrect pressure setting of the Main Relief Valve, which could jeopardize both the safety of the operator and the performance of the machine.

At Ningbo Longerfa Company, we are dedicated to providing solutions to prevent and address such risks, and in this article, we will delve into the critical importance of properly setting the main relief valve in Hitachi EX200-5 excavators. Specifically, we will look into the role of the 4372038 Main Relief Valve, a vital component that canhttps://www.longerfavalves.com/contact-us/ affect the overall performance of the excavator. We will also explore what happens when this valve is set incorrectly, and how this can lead to serious consequences if not properly addressed.

Advanced LS Valve Technology: The 708-2L-04713 LS Valve for Komatsu PC200 Excavator

NINGBO LONGERFA Hydraulic Engineering Machinery Valve Manufacturer is proud to introduce the 708-2L-04713 LS Valve, a high-performance Load Sensing (LS) control valve designed specifically for the Komatsu PC200 excavator. This innovative hydraulic component enhances efficiency, precision, and fuel economy, making it an essential upgrade for construction and excavation machinery.

Quick Troubleshooting Guide for Komatsu PC120-6 Unloading Valve Failure Leading to Weak Performance Komatsu PC120-6 Excavator Hydraulic System – Key Component: Unloading Valve (723-30-56100)

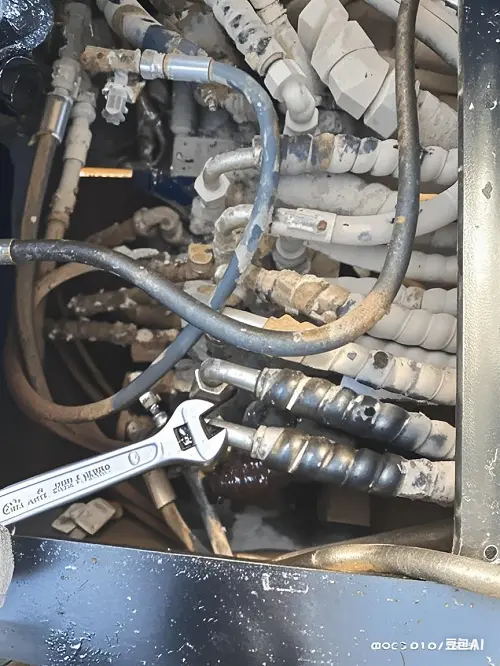

The Komatsu PC120-6 is a reliable excavator widely used in construction and mining. However, one common issue affecting its performance is hydraulic system weakness, often caused by a faulty unloading valve (Part No. 723-30-56100). If your machine is experiencing loss of power, slow operation, or overheating, the unloading valve could be the culprit.

At Ningbo Longerfa Hydraulic Valve Manufacturer, we specialize in high-quality replacement parts, including the Komatsu PC120-6 unloading valve 723-30-56100, ensuring your equipment runs smoothly. This guide provides a quick troubleshooting method to diagnose and resolve unloading valve-related issues efficiently.

PC200-6 Main Control Valve Aging Signals: When is Replacement Necessary? – Expert Guide by Ningbo Longerfa, a Leading Excavator Hydraulic Valve Manufacturer

The main control valve (main pump valve) in a Komatsu PC200-6 excavator is the heart of its hydraulic system, regulating pressure and flow to ensure smooth operation. However, like all hydraulic components, it degrades over time. Ignoring aging symptoms can lead to costly failures, reduced efficiency, and even safety hazards.

As a trusted manufacturer of high-performance main and pilot relief valves for excavators, Ningbo Longerfa provides this comprehensive guide to help operators and technicians identify critical aging signals in the PC200-6 main control valve and determine when replacement is necessary.

Expert Guide: DH55/DH60 Rotary Valve Disassembly, Reassembly & Seal Replacement– Longerfa Hydraulic’s Professional Maintenance Solution for Industrial Valves

As a leading manufacturer of high-performance hydraulic valves, Longerfa Hydraulic specializes in durable and precision-engineered components for construction, agriculture, and industrial machinery. The DH55/DH60 rotary valves are widely used in hydraulic systems due to their reliability and efficiency. However, like all mechanical components, they require periodic maintenance to prevent leaks and ensure smooth operation.

This comprehensive technical guide provides step-by-step instructions for disassembly, seal replacement, and reassembly of DH55/DH60 rotary valves, helping maintenance professionals extend service life and reduce downtime.

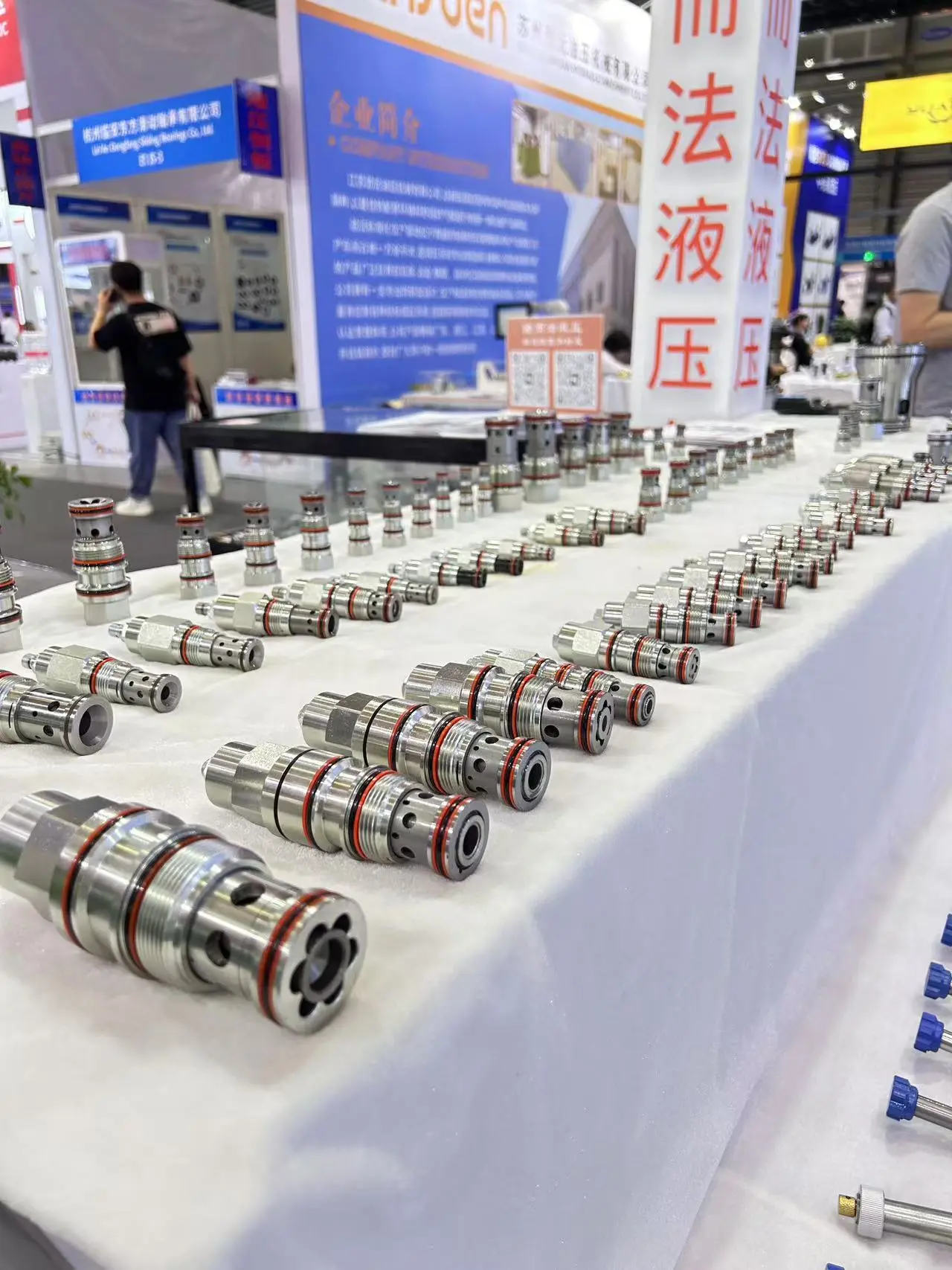

DH220-5 Universal Swing Valve Compatibility Testing: Which Machines Does It Fit? | Longerfa Hydraulic

Longerfa Hydraulic's DH220-5 Universal Swing Valve is engineered to deliver smooth, shock-free rotation control in diverse hydraulic applications. But which machines is it truly compatible with? Our latest rigorous compatibility tests provide the answers.

This valve's compact design, adjustable cushioning, and robust construction make it suitable for integration into various hydraulic systems, from construction equipment to industrial machinery. Below, we break down the key findings from our testing.

DH220-5 Cushion Swing Valve: Working Principle & Adjustment Tips | Longerfa Hydraulic Expert Guide

The DH220-5 Cushion Swing Valve, developed by Longerfa Hydraulic, is a high-performance hydraulic control component widely used in construction machinery, metallurgical equipment, and automated production lines. Its primary function is to smoothly control the rotary motion of hydraulic actuators while minimizing shock and vibration.

This valve features a pilot-operated cushioning adjustment mechanism, which precisely regulates the rotation speed of hydraulic motors or cylinders by adjusting spool opening and throttling resistance. When sudden pressure changes occur in the system, the DH220-5 automatically modulates flow to prevent damage caused by hydraulic shock, thereby extending equipment lifespan and improving operational stability.

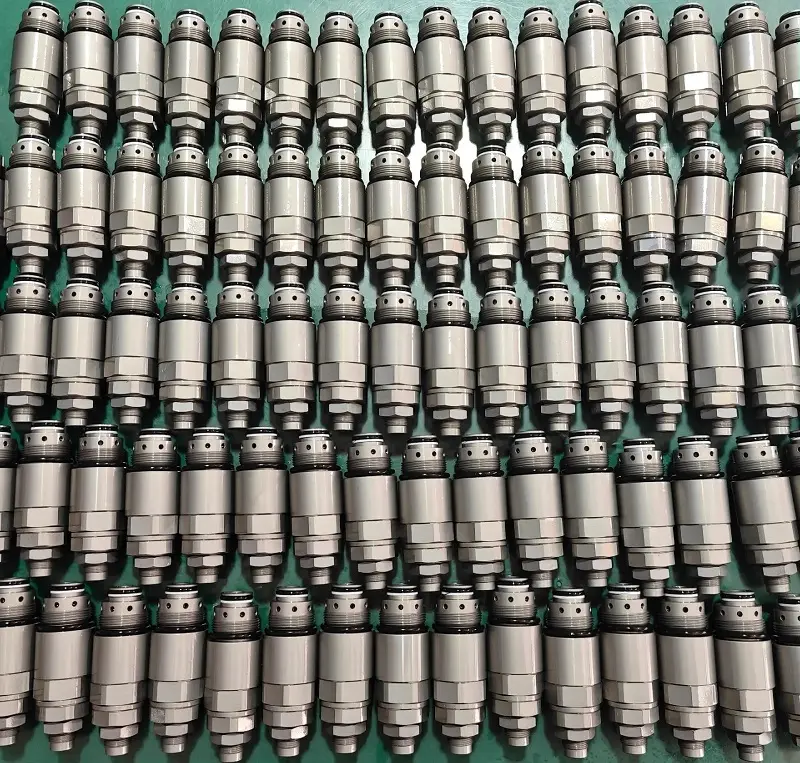

CAT OEM Valves vs Chinese High-Compatibility Valves: Cost & Performance Comparison by Longerfa Hydraulic

Hydraulic control valves are critical components in heavy machinery like Caterpillar (CAT) excavators, ensuring precise movement and optimal performance. When these valves fail, operators face a crucial decision: should they choose expensive OEM (Original Equipment Manufacturer) replacements or more affordable high-compatibility alternatives?

At Longerfa Hydraulic, we specialize in manufacturing high-performance, cost-effective hydraulic valves that meet or exceed OEM standards. In this article, we compare CAT OEM valves with Chinese high-compatibility valves in terms of cost, durability, and performance—helping you make an informed decision for your machinery.

Common Fault Code Analysis for CAT Excavator Control Valves – Expert Insights by Longerfa Hydraulic

CAT excavators are renowned for their durability and performance in heavy-duty construction and mining operations. However, like all hydraulic machinery, their control valves (commonly referred to as "proportional valves" or "main control valves") can develop faults over time. Understanding and diagnosing these faults is crucial for minimizing downtime and ensuring optimal performance.

At Longerfa Hydraulic, a leading manufacturer of high-quality hydraulic components, we specialize in providing reliable solutions for excavator valve systems. In this article, we will explore the most common fault codes related to CAT excavator control valves, their causes, and recommended troubleshooting steps.