Caterpillar Original Factory Valves vs. Domestic High-Compatibility Valves: A Comprehensive Cost and Performance Comparison

1. Overview of Hydraulic Valves in Construction Machinery

Hydraulic valves are crucial components in construction machinery like excavators, bulldozers, and cranes. These valves control the flow and pressure of hydraulic fluid, which powers the machinery’s lifting, digging, and moving functions. They play an essential role in ensuring the efficiency, safety, and longevity of the equipment.

The key valve types used in construction machinery include:

-

Relief Valves: These protect the hydraulic system from excessive pressure. When the pressure exceeds a preset limit, the relief valve opens to divert excess fluid, preventing system damage.

-

Control Valves: These regulate the flow of hydraulic fluid to different parts of the machine, ensuring smooth operation.

-

Check Valves: These ensure that fluid flows in only one direction, preventing backflow.

Two main categories of valves are commonly available:

-

Original Factory Valves (OEM): These valves are made by the equipment manufacturer, such as Caterpillar, and are designed to meet specific engineering standards.

-

Domestic High-Compatibility Valves: These valves are produced by independent manufacturers and are designed to fit a range of machinery, offering compatibility with various models, often at a lower price point.

2. Caterpillar Original Factory Valves: A Closer Look

Caterpillar, one of the world’s leading manufacturers of construction and mining equipment, has a longstanding reputation for producing high-quality, durable parts. Their hydraulic valves, such as the 1057459 Main Relief Valve (CAT312), 310-0395 Relief Valve (CAT320C), and 6E-2273 Relief Valve (CAT320C), are designed specifically for Caterpillar machinery and are engineered to provide optimal performance in demanding construction environments.

Key Advantages of Caterpillar Original Factory Valves:

1. High Performance and Reliability

Caterpillar’s original valves are made with stringent quality control standards and are tested under real-world conditions. They are designed to function seamlessly with Caterpillar machines, ensuring that the hydraulic system operates at maximum efficiency. The original factory valves are built to handle the high pressures and extreme conditions typical of construction machinery, providing superior reliability.

2. Tailored for Specific Machinery

Each Caterpillar valve is engineered for a specific model of machinery, ensuring perfect fitment and compatibility. For instance, the 1057459 Main Relief Valve is specifically designed for the CAT312 excavator, and the 310-0395 Relief Valve is built for the CAT320C model. This means that operators can be confident that the valve will perform optimally and meet the manufacturer's exact specifications.

3. Longevity and Durability

Due to the high standards in materials and manufacturing processes, Caterpillar valves generally have a longer service life compared to aftermarket alternatives. They are resistant to wear and tear, even under harsh conditions, which reduces the frequency of replacements.

4. Excellent Warranty and Support

Purchasing original Caterpillar valves often comes with a warranty and access to customer support from the manufacturer. This can offer peace of mind to operators and fleet managers, knowing that they can rely on the manufacturer’s assistance in case of any issues.

5. Resale Value

For construction companies that frequently buy and sell machinery, using original parts like Caterpillar valves can preserve the equipment’s resale value. Buyers often prefer machines with OEM parts due to their reliability and performance history.

Disadvantages of Caterpillar Original Factory Valves:

1. High Cost

The most significant downside of original Caterpillar valves is their price. Caterpillar products are often more expensive than aftermarket alternatives, as they come with the manufacturer's premium. This can be a significant consideration for smaller businesses or operators looking to minimize costs.

2. Limited Availability

Caterpillar parts may not always be readily available, especially if the machinery is older or less common. In such cases, operators may have to wait for replacement parts, which can lead to extended downtime.

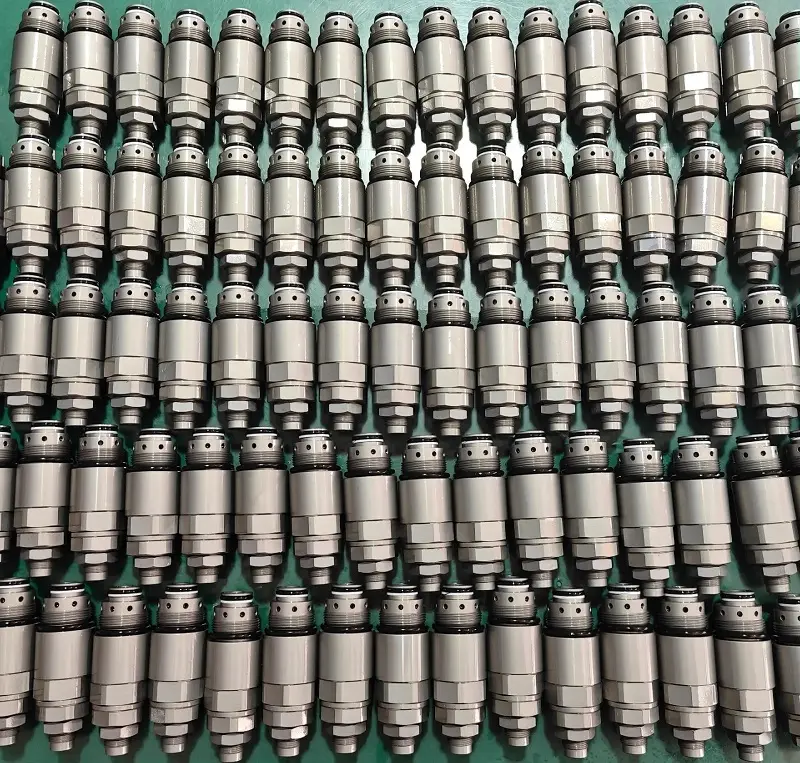

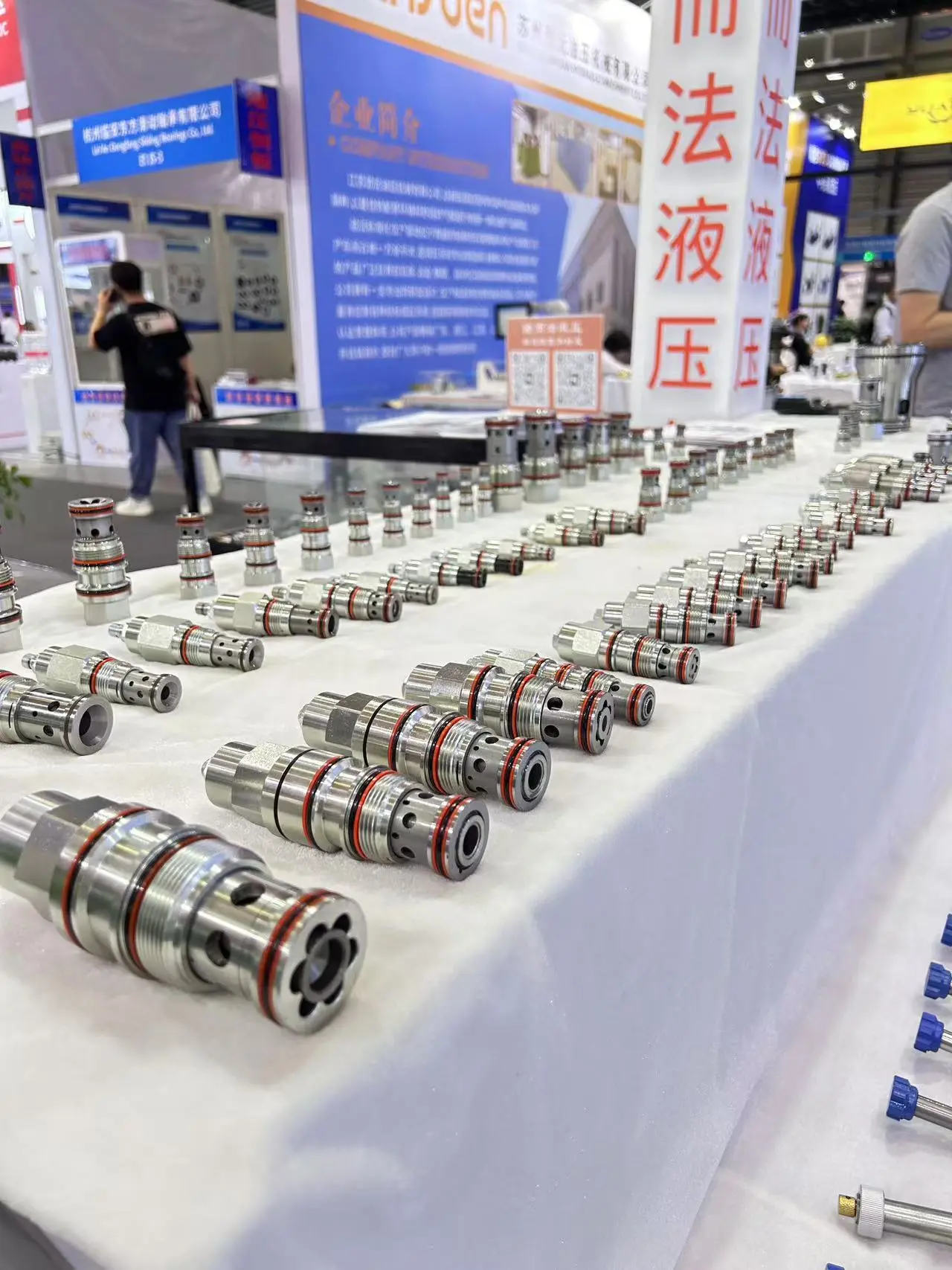

3. Domestic High-Compatibility Valves: An Alternative

Domestic high-compatibility valves are produced by independent manufacturers and are designed to work with a variety of machinery models, including those from well-known brands like Caterpillar. These valves are often marketed as more affordable alternatives to OEM parts, offering similar functionality at a fraction of the cost.

Key Advantages of Domestic High-Compatibility Valves:

1. Lower Cost

The primary advantage of domestic high-compatibility valves is their cost. These valves are generally much more affordable than original equipment valves. For companies that need to replace multiple valves or operate several machines, the savings can be significant.

2. Wide Compatibility

Domestic valves are often designed to be compatible with a wide range of machinery from different manufacturers. This can be beneficial for fleet managers who operate mixed fleets of equipment and want to standardize the parts across multiple machines.

3. Availability

Aftermarket valves are often readily available, even for older machinery. With a larger number of manufacturers producing these parts, availability can be a lot better than with OEM valves, reducing downtime when a replacement is needed.

Disadvantages of Domestic High-Compatibility Valves:

1. Potential Compatibility Issues

While these valves are designed to be compatible with multiple machines, there’s a risk that they may not perform as well as original parts. Even slight deviations in design or material can lead to reduced performance, increased wear, or even system failure. Domestic valves may not always meet the rigorous engineering standards of OEM parts.

2. Shorter Lifespan

In general, domestic high-compatibility valves may have a shorter service life compared to original factory valves. They are often made with less expensive materials, which can result in greater wear and tear over time.

3. Limited Support and Warranty

While some aftermarket valve manufacturers offer warranties, the support may not be as comprehensive as what comes with OEM parts. Additionally, warranty claims can be more complicated when it comes to non-original components.

4. Cost vs. Performance: Which is Better?

When comparing Caterpillar original factory valves with domestic high-compatibility valves, the decision comes down to balancing cost with performance.

-

If your priority is reliability and long-term durability, the Caterpillar original factory valves such as the 1057459 Main Relief Valve (CAT312), 310-0395 Relief Valve (CAT320C), and 6E-2273 Relief Valve (CAT320C) are the best option. These valves are engineered specifically for Caterpillar equipment and are likely to offer superior performance, especially under harsh working conditions. The higher upfront cost is justified by the long-term savings on repairs, downtime, and increased machinery lifespan.

-

If you are looking to cut costs and are willing to accept potential trade-offs in performance and longevity, domestic high-compatibility valves may be a viable option. These valves can offer immediate savings and are particularly useful for older equipment or when the budget is tight. However, operators should be aware that cheaper valves might require more frequent replacements and may not always perform as efficiently as OEM valves.

5. Conclusion

Both Caterpillar original factory valves and domestic high-compatibility valves have their merits and drawbacks. For businesses focused on long-term reliability and performance, the higher cost of original Caterpillar valves may be worth the investment. On the other hand, for companies with tighter budgets or those operating in less demanding environments, high-compatibility domestic valves can provide a cost-effective alternative.

When making a decision, it’s important to consider factors like the age of your machinery, the operating conditions, and the total cost of ownership over the lifespan of the valve. For those in search of high-quality valves for Caterpillar equipment, Ningbo Longerfa offers a variety of compatible and reliable valves, including the 1057459 Main Relief Valve (CAT312) and 310-0395 Relief Valve (CAT320C). Whatever your choice, ensuring that you select the right valve is crucial for maintaining the performance and longevity of your construction machinery.

About Ningbo Longerfa

Ningbo Longerfa is a professional manufacturer of construction machinery valves, committed to delivering high-quality products at competitive prices. We specialize in producing valves that are compatible with a wide range of construction machinery, including products like the 1057459 Main Relief Valve and the 310-0395 Relief Valve. Our goal is to provide our customers with reliable, cost-effective solutions to meet their equipment needs.