Common Fault Code Analysis for CAT Excavator Control Valves – Expert Insights by Longerfa Hydraulic

Common CAT Excavator Control Valve Fault Codes

1. Fault Code: 2345 – "Pump Control Valve Current Below Normal"

Symptoms:

-

Reduced hydraulic power

-

Slow or unresponsive movements

-

Engine stalling under load

Possible Causes:

-

Faulty solenoid coil

-

Wiring harness damage or poor connections

-

Contaminated hydraulic fluid affecting valve spool movement

Solutions:

-

Check solenoid resistance with a multimeter (should be within OEM specifications).

-

Inspect wiring for corrosion or breaks.

-

Replace the control valve if internal wear is detected.

2. Fault Code: 1892 – "Pressure Sensor Signal Abnormal"

Symptoms:

-

Erratic boom or arm movements

-

Hydraulic System overheating

-

Intermittent loss of power

Possible Causes:

-

Faulty pressure sensor

-

Clogged or damaged sensor lines

-

Electrical interference or poor grounding

Solutions:

-

Test the pressure sensor output with diagnostic tools.

-

Clean or replace blocked hydraulic lines.

-

Ensure proper grounding of the valve control system.

3. Fault Code: 3226 – "Valve Spool Stuck or Not Responding"

Symptoms:

-

Jerky or uneven cylinder movements

-

Inability to hold loads (drift)

-

Unusual hydraulic noises

Possible Causes:

-

Contaminants in hydraulic oil causing spool sticking

-

Worn valve spool or housing

-

Low hydraulic fluid levels

Solutions:

-

Flush the hydraulic system and replace filters.

-

Inspect the valve spool for scoring or wear.

-

Use high-quality hydraulic fluid to prevent future contamination.

4. Fault Code: 4110 – "Solenoid Valve Short Circuit"

Symptoms:

-

Complete loss of function in one or more hydraulic circuits

-

Blown fuses or electrical failures

Possible Causes:

-

Damaged solenoid windings

-

Water ingress causing corrosion

-

Excessive voltage spikes

Solutions:

-

Replace the defective solenoid.

-

Check the control module for proper voltage output.

-

Seal electrical connectors to prevent moisture damage.

5. Fault Code: 2891 – "Pilot Pressure Too Low"

Symptoms:

-

Weak or sluggish excavator movements

-

Inconsistent operation of auxiliary hydraulics

Possible Causes:

-

Worn pilot pump

-

Leaking pilot lines or seals

-

Faulty pressure relief valve

Solutions:

-

Measure pilot pressure with a gauge.

-

Replace damaged seals or hoses.

-

Adjust or replace the pressure relief valve if necessary.

Preventive Maintenance Tips for CAT Excavator Control Valves

To avoid frequent valve-related faults, Longerfa Hydraulic recommends the following best practices:

-

Regular Fluid Checks – Use high-quality hydraulic oil and change it at recommended intervals.

-

Filter Replacement – Clogged filters are a leading cause of valve contamination.

-

Electrical Inspections – Check wiring harnesses and connectors for wear or corrosion.

-

Valve Calibration – Periodically verify solenoid operation and pressure settings.

-

Professional Diagnostics – Use CAT ET or compatible diagnostic tools for accurate troubleshooting.

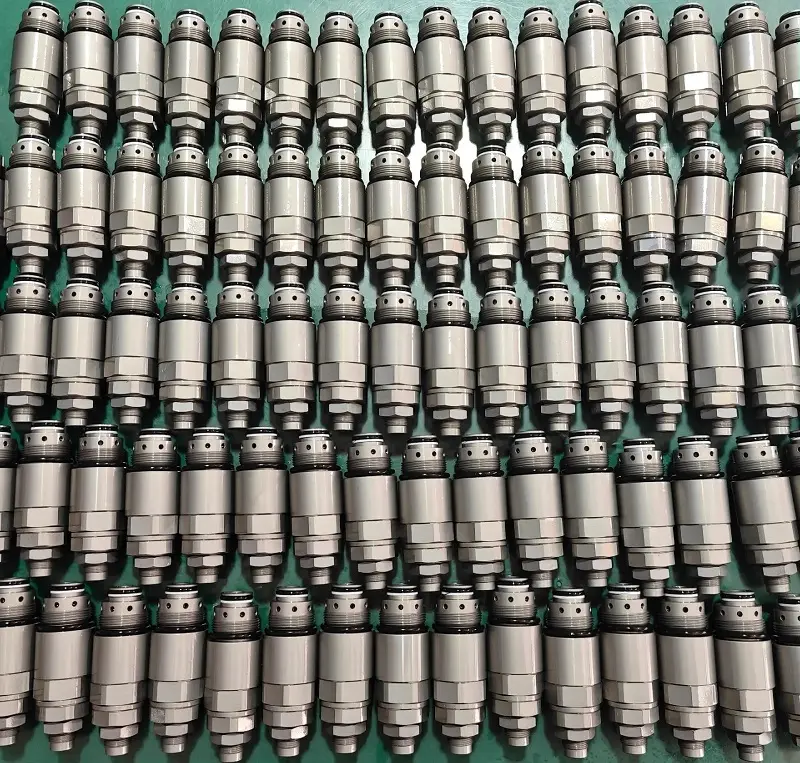

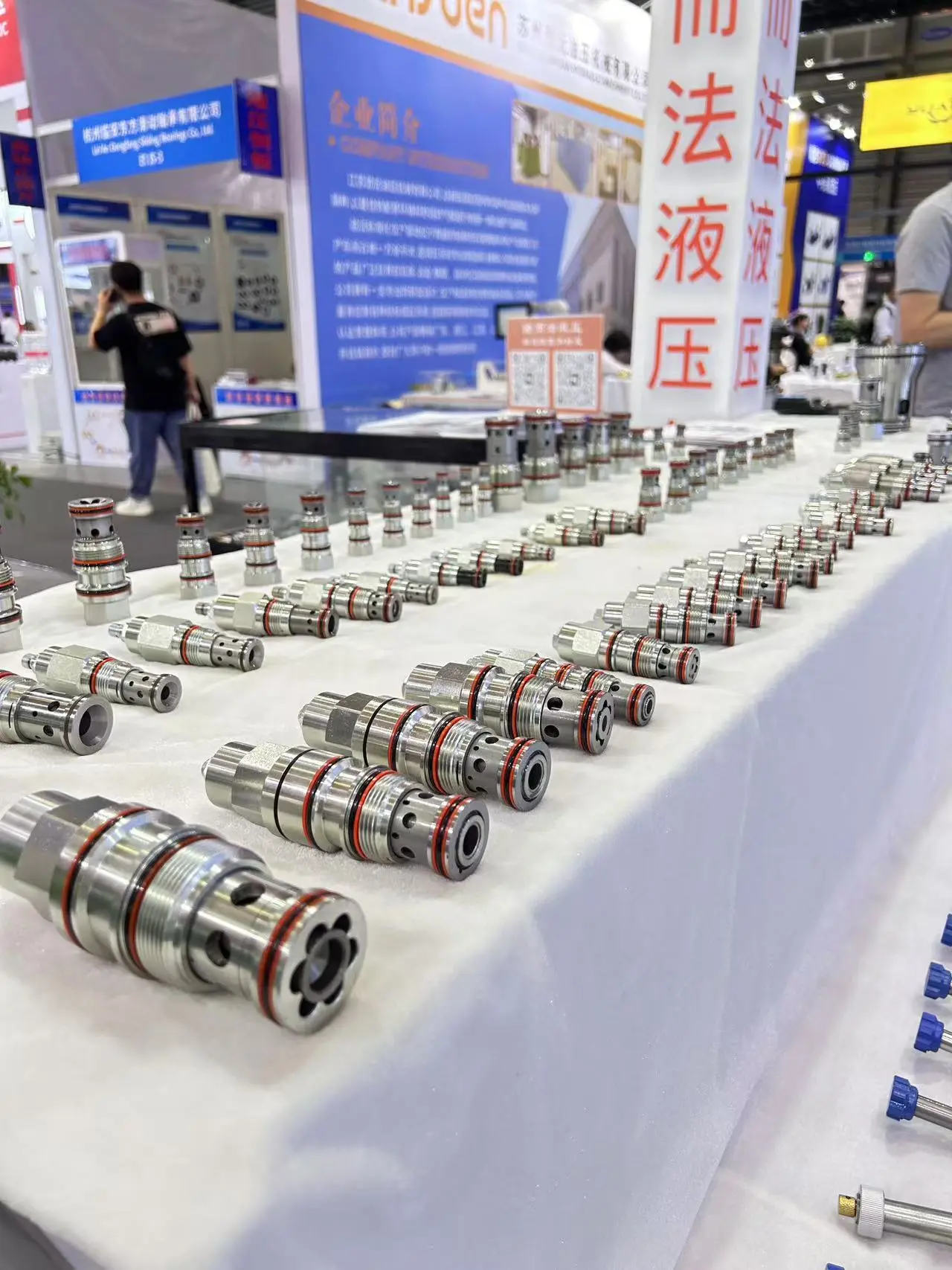

Why Choose Longerfa Hydraulic for Your Excavator Valve Needs?

At Longerfa Hydraulic, we design and manufacture high-performance control valves, solenoid coils, and hydraulic components that meet or exceed OEM standards. Our products are rigorously tested for durability and compatibility with CAT excavators, ensuring long-term reliability.

Our Advantages:

✅ Direct Replacement Parts – Perfect fit for CAT excavator models.

✅ Enhanced Durability – Precision-engineered for harsh working conditions.

✅ Competitive Pricing – Cost-effective solutions without compromising quality.

✅ Global Support – Fast shipping and technical assistance worldwide.

For more information on our hydraulic solutions, visit our website or contact our expert team today!

Conclusion:

Understanding CAT excavator control valve fault codes is essential for efficient troubleshooting and maintenance. By following the guidelines above and choosing Longerfa Hydraulic for replacement parts, you can ensure maximum uptime and performance for your machinery.

Stay ahead with Longerfa – Your Trusted Hydraulic Solutions Provider!