Comprehensive Guide to Troubleshooting Slow Excavator Valve Groups: Hydraulic Solutions by Ningbo Longerfa

Common Causes of Slow Excavator Movements

1. Faulty Hydraulic Pressure Relief Valve

A malfunctioning Hydraulic Pressure Relief Valve | can lead to insufficient pressure regulation, causing slow or weak excavator movements. Symptoms include:

-

Delayed cylinder response

-

Reduced digging force

-

Overheating hydraulic fluid

Solution: Inspect the relief valve for wear, contamination, or improper settings. Replace if necessary with high-performance valves from Ningbo Longerfa’s product line.

2. Clogged or Worn Excavator Relief Valves

Dirt, debris, or metal particles can obstruct Excavator relief valves, restricting fluid flow and reducing operational speed.

Solution:

-

Disassemble and clean the valve group

-

Check for internal damage

-

Upgrade to Pilot-Operated Relief Valves for better filtration resistance

3. Incorrect Pressure Settings in Direct-Acting Relief Valves

Direct-Acting Relief Valves respond quickly to pressure spikes but may lose calibration over time, leading to sluggish performance.

Solution:

-

Verify pressure settings using a hydraulic gauge

-

Adjust according to manufacturer specifications

-

Consider replacing with a more stable Pilot-Operated Relief Valve

4. Leaks in the Hydraulic System

Internal or external leaks reduce system pressure, affecting valve responsiveness.

Solution:

-

Inspect hoses, seals, and valve connections

-

Use high-quality Hydraulic Pressure Relief Valve | components to prevent future leaks

Step-by-Step Valve Group Troubleshooting

Step 1: Check Hydraulic Fluid Condition

-

Contaminated or degraded fluid can cause valve malfunctions.

-

Replace fluid and filters if necessary.

Step 2: Test Pump Output Pressure

-

Low pump pressure indicates a failing pump or relief valve issue.

-

Compare readings with OEM specifications.

Step 3: Inspect Excavator Relief Valves

-

Remove and examine Excavator relief valves for wear or blockages.

-

Clean or replace with precision-engineered valves from Longerfa’s selection.

Step 4: Evaluate Pilot-Operated Relief Valves

-

Pilot-Operated Relief Valves provide finer pressure control but require regular maintenance.

-

Ensure pilot lines are unobstructed and diaphragms are intact.

Step 5: Verify Electrical Controls (if applicable)

-

Faulty solenoids can delay valve actuation.

-

Test wiring and replace defective components.

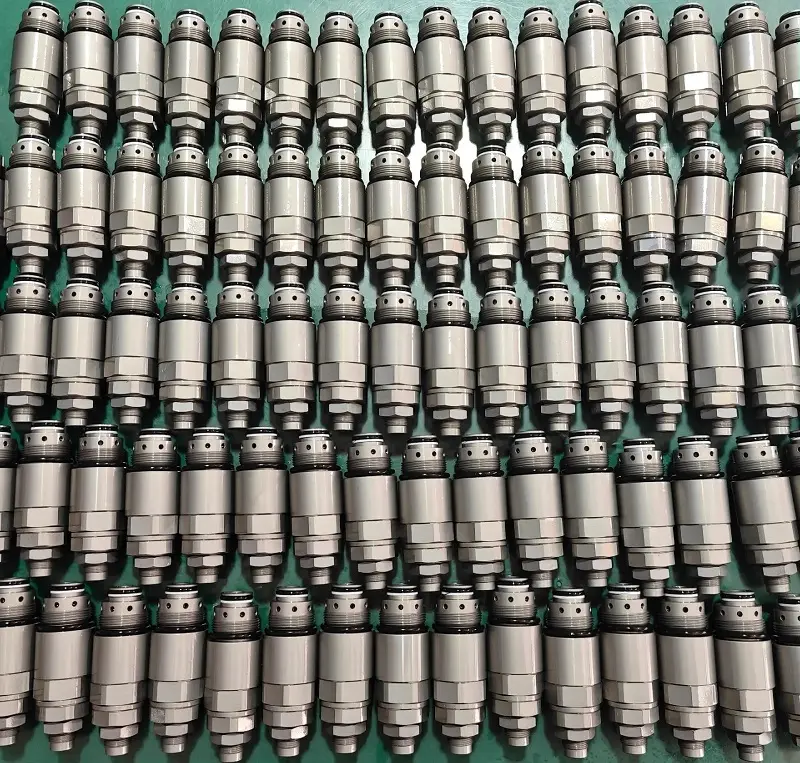

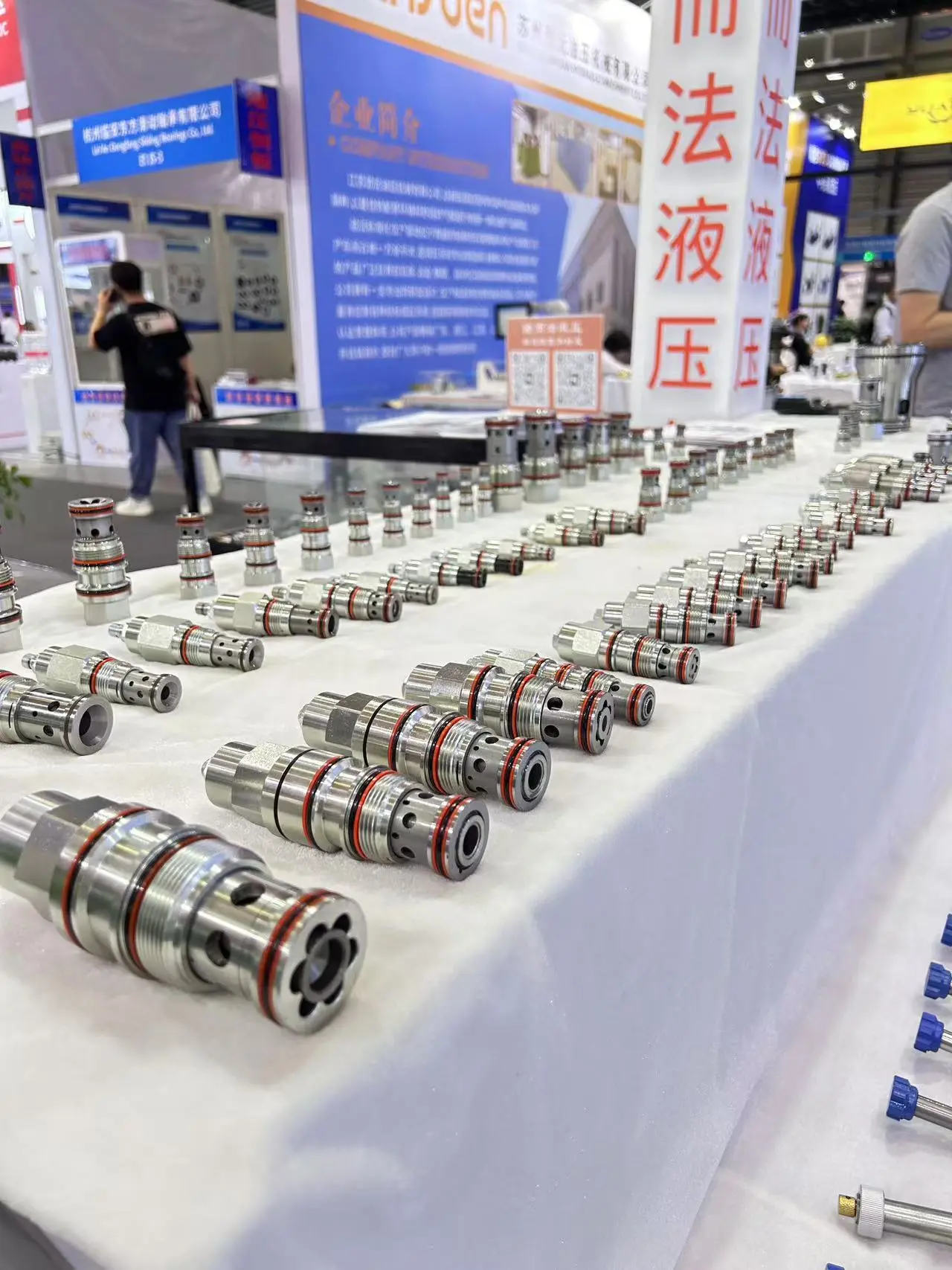

Why Choose Ningbo Longerfa’s Hydraulic Valves?

As a trusted hydraulic solutions provider, Ningbo Longerfa Hydraulic Co., Ltd specializes in:

-

High-Precision Hydraulic Pressure Relief Valve | systems

-

Durable Excavator relief valves for heavy-duty applications

-

Responsive Direct-Acting Relief Valves for instant pressure regulation

-

Advanced Pilot-Operated Relief Valves for superior flow control

Our products ensure:

✔ Extended valve lifespan

✔ Consistent hydraulic performance

✔ Reduced downtime for excavators

For reliable replacements, explore our valve product range.

Conclusion

Slow excavator movements often stem from valve group issues, particularly Hydraulic Pressure Relief Valve | failures. By systematically inspecting Excavator relief valves, Direct-Acting Relief Valves, and Pilot-Operated Relief Valves, operators can restore optimal performance.

For premium hydraulic components, trust Ningbo Longerfa Hydraulic Co., Ltd—your partner in efficient, durable excavator solutions. Visit our product page today!