How Hydraulic Cartridge Valves Improve System Efficiency in Heavy Machinery

What Are Hydraulic Cartridge Valves?

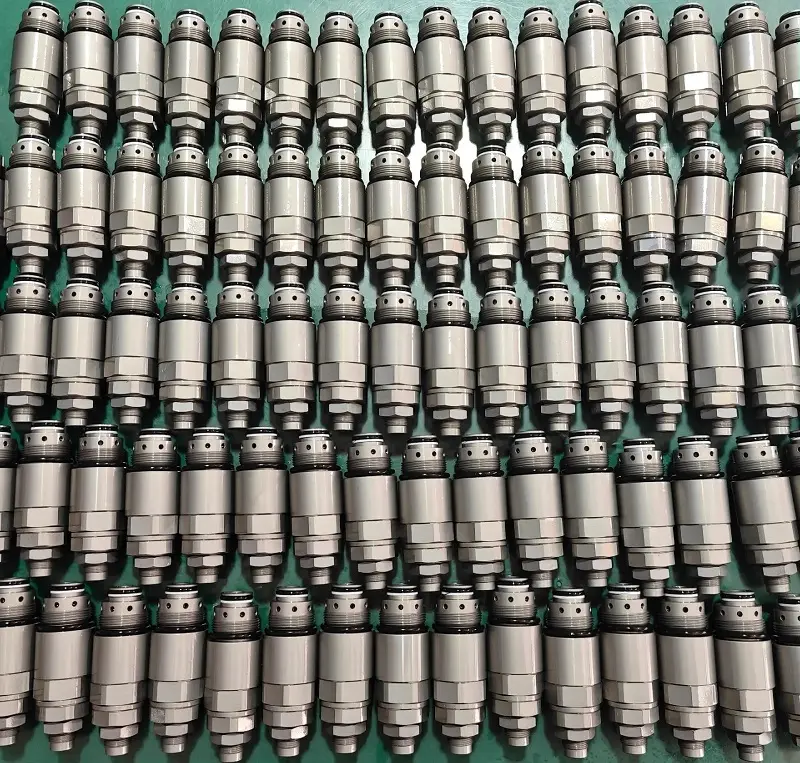

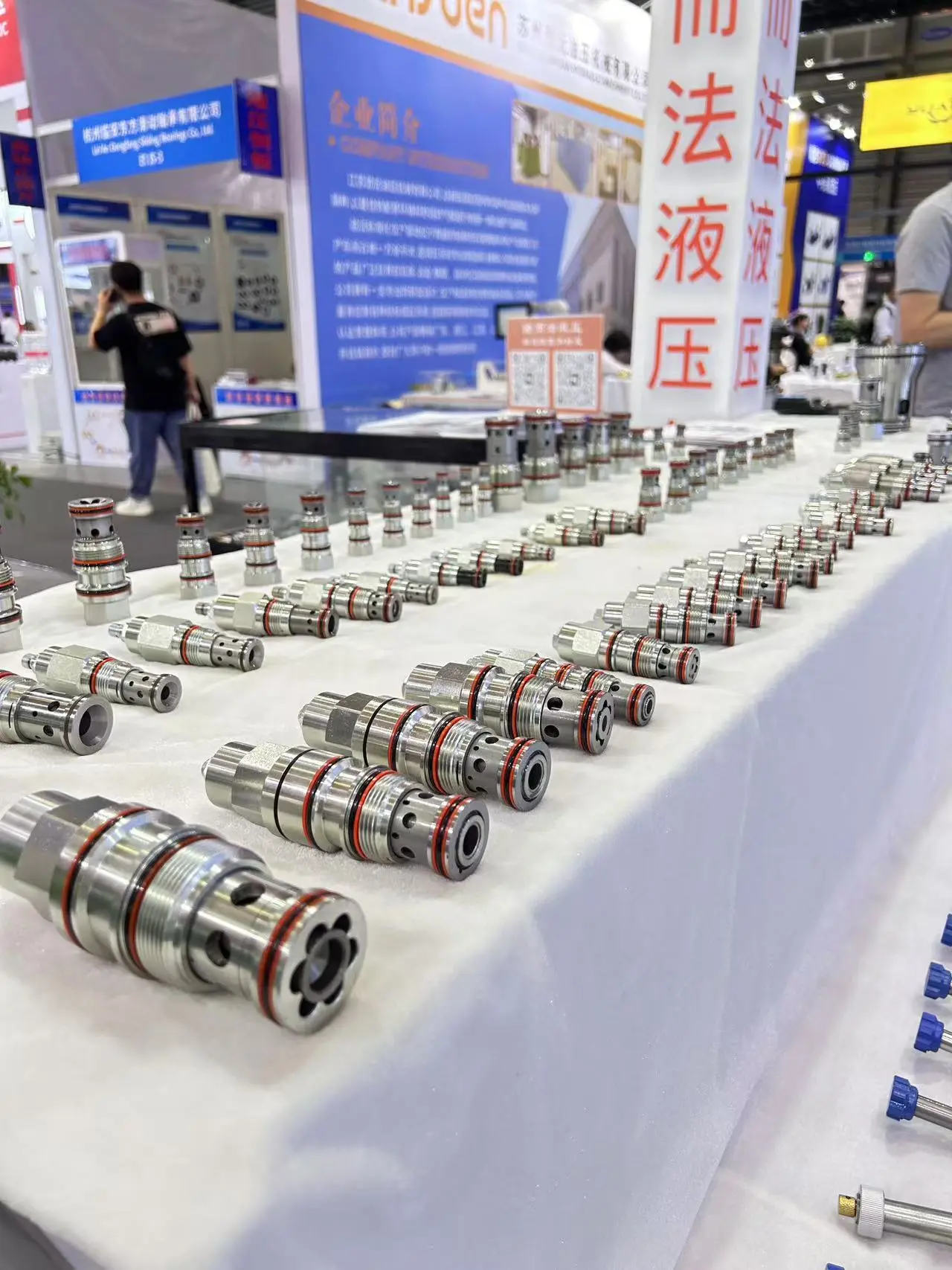

Hydraulic cartridge valves are compact, modular components that control the flow, pressure, and direction of hydraulic fluid within a system. These valves are typically inserted into a valve body or manifold, making them easy to replace, maintain, and upgrade without the need to disassemble the entire system.

The cartridge valve is an integral part of any Hydraulic System, especially in heavy machinery such as excavators. They come in various types, including relief, check, directional, and pressure-regulating valves. Each type serves a specific function, but all contribute to optimizing the performance of hydraulic systems.

Role of Excavator Relief Valvesin Hydraulic Systems

One of the most critical hydraulic cartridge valves in an excavator system is the excavator relief valve. The relief valve’s primary role is to regulate the pressure within the hydraulic system, ensuring that it doesn’t exceed preset limits. By maintaining optimal pressure levels, the relief valve protects the hydraulic components from damage due to excessive pressure, ensuring the longevity and reliability of the system.

When an excavator operates under heavy load conditions, the system pressure can rise beyond the safety threshold. This is where the excavator relief valve steps in, diverting excess pressure away from sensitive parts of the system and preventing potential failures. Without a properly functioning relief valve, the entire hydraulic system could be at risk of catastrophic failure.

Improved System Efficiency with Hydraulic Cartridge Valves

-

Precision Control of Hydraulic Flow

One of the most significant advantages of hydraulic cartridge valves, such as excavator relief valves, is the level of precision they offer in controlling the flow of hydraulic fluid. These valves are designed to respond quickly to changes in pressure or flow, ensuring that the hydraulic fluid is directed exactly where it is needed within the system.

In an excavator, for example, the relief valve ensures that pressure is maintained at optimal levels throughout various functions, whether it’s lifting, digging, or rotating. By preventing sudden pressure spikes or drops, the system operates more smoothly, enhancing the overall efficiency of the machine.

-

Energy Efficiency

Energy consumption is a significant concern for the operation of heavy machinery. Traditional hydraulic systems can often waste energy due to inefficiencies in fluid flow and pressure management. However, hydraulic cartridge valves help mitigate this by providing precise pressure control. When the system operates at its optimal pressure, there is less energy wasted, and the system consumes less fuel.

In excavators, this means that the engine can work more efficiently because the hydraulic system is not putting unnecessary strain on the engine. As a result, the operator benefits from faster response times, while the company enjoys reduced fuel costs and improved productivity.

-

Minimized Downtime and Maintenance Costs

Hydraulic cartridge valves are known for their durability and longevity. By integrating these valves into an excavator’s hydraulic system, manufacturers can significantly reduce the risk of system failure and downtime. Since these valves are modular, they can be easily replaced or serviced without having to overhaul the entire system.

The excavator relief valve plays a crucial role in this aspect. If the relief valve is functioning correctly, the risk of over-pressurization is minimized, which, in turn, reduces the likelihood of system breakdowns. Regular maintenance and timely replacement of worn-out valves ensure that the excavator continues to operate efficiently without the need for costly repairs.

-

Simplified Design and Integration

Hydraulic cartridge valves simplify the design and integration of hydraulic systems. Since they are compact and modular, engineers can easily design systems that are more streamlined and space-efficient. This is especially important in large machines like excavators, where space is often limited.

By integrating cartridge valves, manufacturers can reduce the overall size and complexity of the hydraulic manifold, leading to fewer components and lower overall system weight. In turn, this results in a more efficient machine that performs better in the field.

-

Improved Operator Experience

The efficiency of a hydraulic system is not only measured by the performance of the machine but also by the experience of the operator. Hydraulic cartridge valves, particularly relief valves, improve the responsiveness and control of heavy machinery. For excavator operators, this means smoother operation and more precise handling of the machine.

With precise control over the pressure and flow of the hydraulic system, operators can make finer adjustments and execute tasks more efficiently. This results in better performance on job sites, reducing time spent on each task and boosting productivity.

-

Environmental Benefits

Finally, hydraulic cartridge valves help reduce the environmental impact of heavy machinery. With improved efficiency and reduced fuel consumption, excavators and other machinery can operate with a smaller carbon footprint. Additionally, by reducing the likelihood of system failure, the lifespan of the equipment is extended, which also contributes to reducing the overall environmental impact of manufacturing and disposal.

Conclusion

Hydraulic cartridge valves, such as the excavator relief valve, have revolutionized the performance of hydraulic systems in heavy machinery. By providing precise control over fluid flow and pressure, they improve energy efficiency, reduce downtime, and minimize the need for expensive repairs. These valves not only enhance the overall performance of excavators and other heavy machinery but also contribute to environmental sustainability.

For companies looking to optimize their equipment and maximize productivity, investing in high-quality hydraulic cartridge valves is a crucial step toward achieving long-term success. With their reliability, precision, and efficiency, hydraulic cartridge valves are a key component in the next generation of heavy machinery.