How to Select the Right Hydraulic Cartridge Valve for Your System

Understanding Cartridge Valves

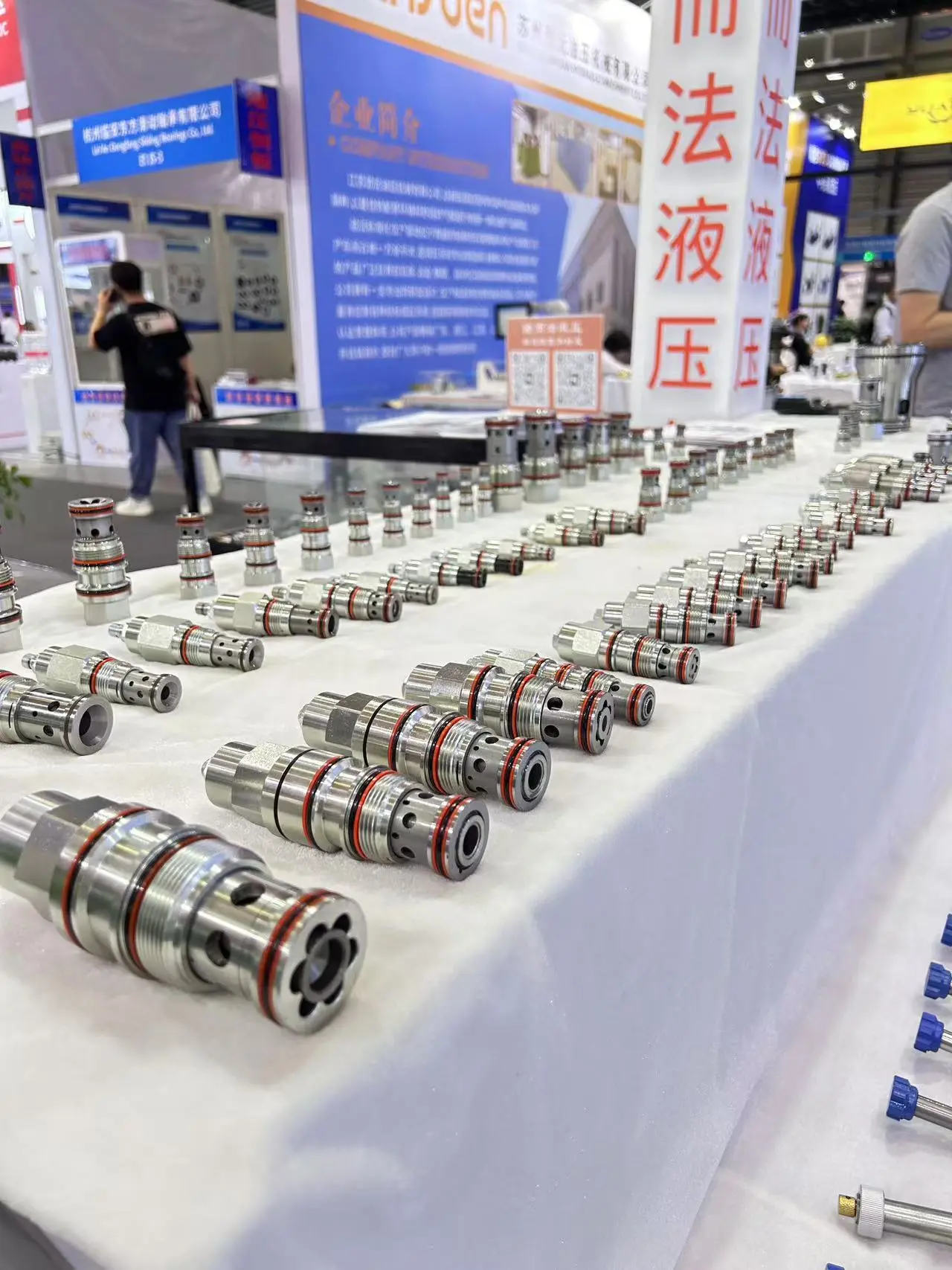

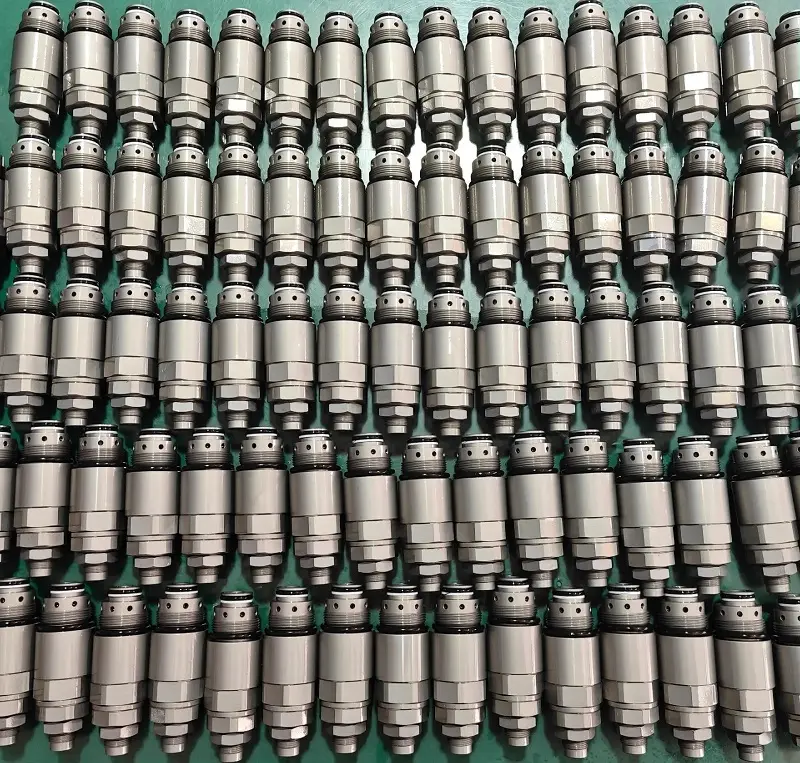

A hydraulic cartridge valve is a compact, modular valve designed to control flow, pressure, or direction in Hydraulic Systems. Installed in custom or standardized cavities, these valves are favored for their flexibility, serviceability, and high performance under demanding conditions.

Common types of hydraulic cartridge valves include:

-

Pressure Control Valves (relief, reducing, unloading)

-

Flow Control Valves

-

Directional Control Valves

-

Check Valves

-

Proportional Valves

These valves are widely used in construction machinery, agricultural equipment, industrial presses, and mobile hydraulics—areas where Ningbo Longerfa has a strong presence and proven expertise.

Key Factors to Consider When Selecting a Hydraulic Cartridge Valve

1. System Requirements and Function

Before choosing a valve, define its function within the system:

-

Is it controlling pressure, flow, or direction?

-

Should it operate manually, electrically, or hydraulically?

-

Is proportional control needed?

For example, if you’re working on an excavator’s boom circuit and need smooth, adjustable flow, a proportional flow control valve might be required. For safety and overload protection, a pressure relief valve is essential.

At Longerfa, our engineering team can help analyze your system’s needs and recommend the most suitable valve solution.

2. Working Pressure and Flow Rate

Each cartridge valve is designed to handle specific pressure and flow ratings. Exceeding these can result in failure, leakage, or performance loss.

-

Pressure ratings commonly range from 210 to 350 bar (3,000–5,000 psi), depending on the valve type and material.

-

Flow ratings vary based on cavity size and internal geometry.

Longerfa valves are engineered with high-strength materials and precision machining to handle rigorous pressures and flows, especially in heavy-duty construction equipment.

3. Valve Cavity and Mounting Type

Hydraulic cartridge valves are installed in standardized or custom cavities. Selecting the correct cavity is crucial for compatibility.

-

Standard cavities (per ISO or SAE specifications) simplify replacement and global sourcing.

-

Custom cavities allow tailored flow characteristics but may limit interchangeability.

Ningbo Longerfa produces valves compatible with international cavity standards and offers customized designs for OEM requirements.

4. Material and Sealing Compatibility

Valves should be constructed from materials that withstand environmental and fluid conditions.

-

Steel or hardened steel bodies are ideal for high-pressure, high-wear applications.

-

Aluminum bodies may be used in weight-sensitive or lower-pressure systems.

-

Seals (NBR, Viton, EPDM) must match the hydraulic fluid type and temperature range.

Longerfa’s quality assurance program ensures all materials meet international standards, and our engineers will help select seal kits suited for your working fluid and operating environment.

5. Control Method and Actuation

Hydraulic cartridge valves can be:

-

Manually operated (levers, knobs)

-

Electrically actuated (solenoid valves)

-

Hydraulically or pneumatically controlled

For construction machinery, electro-hydraulic actuation is becoming the standard for precision control and remote operation.

Longerfa’s valve portfolio includes a full range of actuated cartridge valves, from simple relief valves to advanced proportional control units.

6. Response Time and Accuracy

For dynamic systems, especially in mobile machinery, the speed and precision of valve operation can significantly affect performance.

-

Directional valves need fast switching for accurate motion control.

-

Proportional valves require fine resolution for load-sensitive operations.

Our high-response valves are engineered for rapid reaction and minimal pressure drop—ideal for excavators, loaders, and cranes.

Custom Solutions for OEMs and Machine Builders

At Ningbo Longerfa, we don't just offer catalog valves—we partner with OEMs and system integrators to deliver customized valve solutions. Our in-house R&D team works with clients to:

-

Develop bespoke cartridge valves for unique applications

-

Optimize performance-to-cost ratios

-

Conduct testing and simulation to ensure system reliability

Whether you need a custom cavity, special flow characteristics, or application-specific packaging, we deliver precision-engineered components that integrate seamlessly into your hydraulic system.

Why Choose Ningbo Longerfa Hydraulic Co., Ltd.?

✅ Industry Expertise

With over 15 years in the hydraulic valve industry, Longerfa serves leading names in construction machinery and mobile equipment sectors.

✅ Complete Product Line

From pressure relief valves to directional control valves, we offer a full suite of hydraulic cartridge valves.

✅ Customization and R&D

We provide tailored solutions for OEMs with unique system requirements, supported by robust engineering and testing capabilities.

✅ Quality Manufacturing

Our facilities use advanced CNC machining, automated assembly, and rigorous quality control to ensure performance and consistency.

✅ Global Support

We export to Southeast Asia, the Middle East, Europe, North America, and beyond—offering technical support, timely delivery, and flexible logistics.

Final Thoughts

Choosing the right hydraulic cartridge valve is more than selecting a part—it’s about ensuring system efficiency, safety, and durability. At Ningbo Longerfa Hydraulic Co., Ltd., we help you make the right choice based on engineering expertise, field experience, and a deep understanding of hydraulic systems.

Whether you’re building a new excavator, servicing a hydraulic pump station, or upgrading your mobile equipment fleet, Longerfa is your trusted partner for reliable, high-performance hydraulic solutions.

Contact us today to learn more about our hydraulic cartridge valves or to speak with an application engineer. We’re here to help you build stronger, smarter hydraulic systems.

📧 Email: ken@longerfavalve.com

🌐 Website: www.longerfavalves.com

📍 Location: Ningbo, China