Hydraulic Valve Failures in Construction Machinery: Causes and Prevention

Common Causes of Hydraulic Valve Failures

-

Contaminated Hydraulic Fluid

Contaminants such as dirt, water, or metal particles are the number one enemy of hydraulic components. When contaminants enter the Hydraulic System, they can damage valve surfaces, clog orifices, and lead to improper sealing, eventually causing relief valves to stick or malfunction. -

Improper Installation

Installing a valve without proper alignment, torque, or cleanliness can lead to early failure. In the case of cartridge valves, misalignment in the cavity or insufficient tightening can result in internal leakage or system inefficiencies. -

Overpressure Events

Relief valves are designed to protect hydraulic systems from pressure spikes. However, if they are not rated correctly for the system's pressure range or if they fail to open at the correct pressure, critical system damage can occur. -

Poor-Quality Materials

Substandard materials used in manufacturing valves can corrode, fatigue, or wear out quickly, especially in high-pressure and high-temperature environments common in construction applications. -

Inadequate Maintenance

Ignoring regular inspection and replacement schedules for hydraulic components increases the risk of sudden failure. Valves, like any other mechanical part, wear over time and require proactive maintenance. -

Design or Manufacturing Defects

Sometimes, the failure lies in the product itself. Poor tolerance control, inadequate surface finishing, or outdated designs can all contribute to early failure.

Prevention: How to Avoid Hydraulic Valve Failures

-

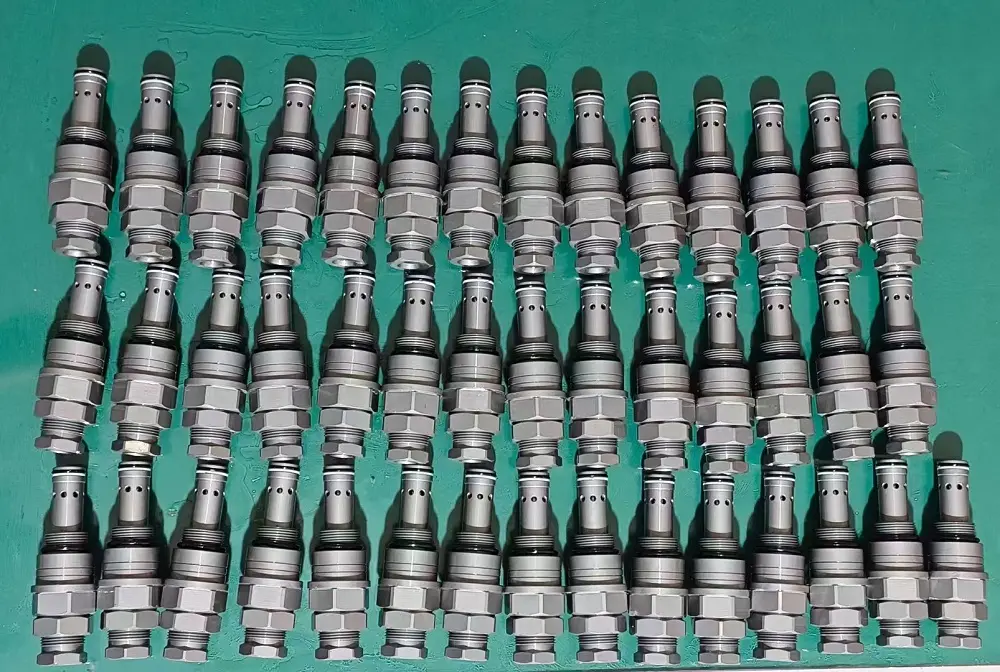

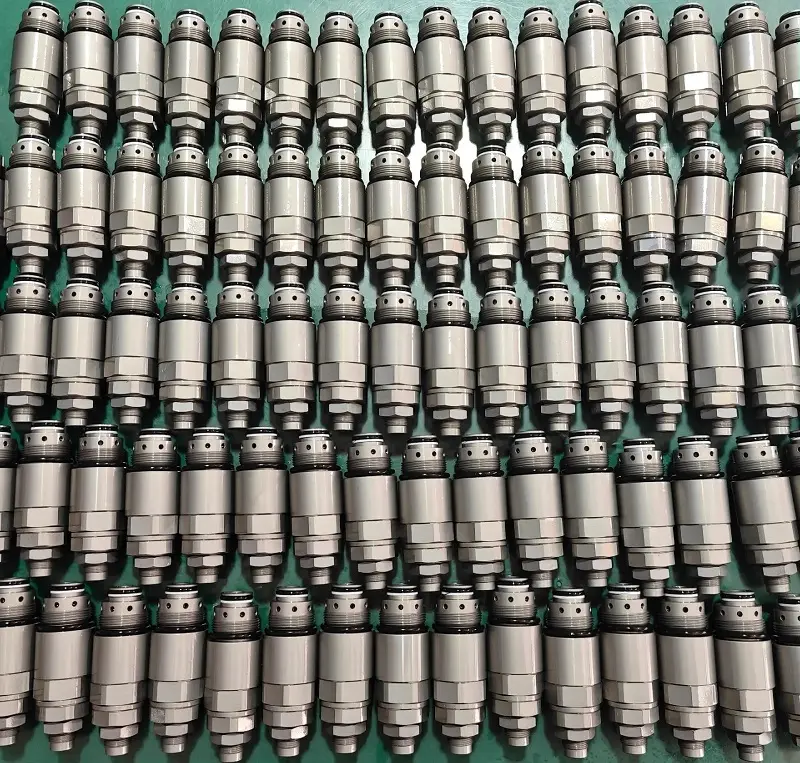

Choose a Trusted Manufacturer

Partnering with a manufacturer who emphasizes quality, precision, and testing is critical. At Longerfa Hydraulic, we use high-grade materials, CNC-machined components, and rigorous testing protocols to ensure every valve meets or exceeds international performance standards. -

Implement Filtration Systems

Effective hydraulic fluid filtration helps prevent contamination-related issues. We recommend systems with filters rated to capture particles as small as 10 microns, along with regular fluid analysis. -

Use Correct Valve Specifications

Selecting the right valve for your application—considering flow rate, pressure range, fluid type, and temperature—is key to long-term reliability. Our engineering team works closely with OEMs and maintenance departments to provide customized solutions for each application. -

Schedule Regular Maintenance

Develop a maintenance calendar based on operating hours and usage intensity. Inspect relief valves for signs of wear, leakage, or inconsistent operation, and replace them before failure occurs. -

Train Technicians Properly

Ensure that installation and service personnel are trained in valve operation, maintenance, and installation procedures. Even a high-quality valve can fail if it’s installed incorrectly. -

Utilize Valve Testing Services

Longerfa offers valve performance testing and analysis services for OEMs and global partners, helping to ensure the reliability of their systems before products hit the field.

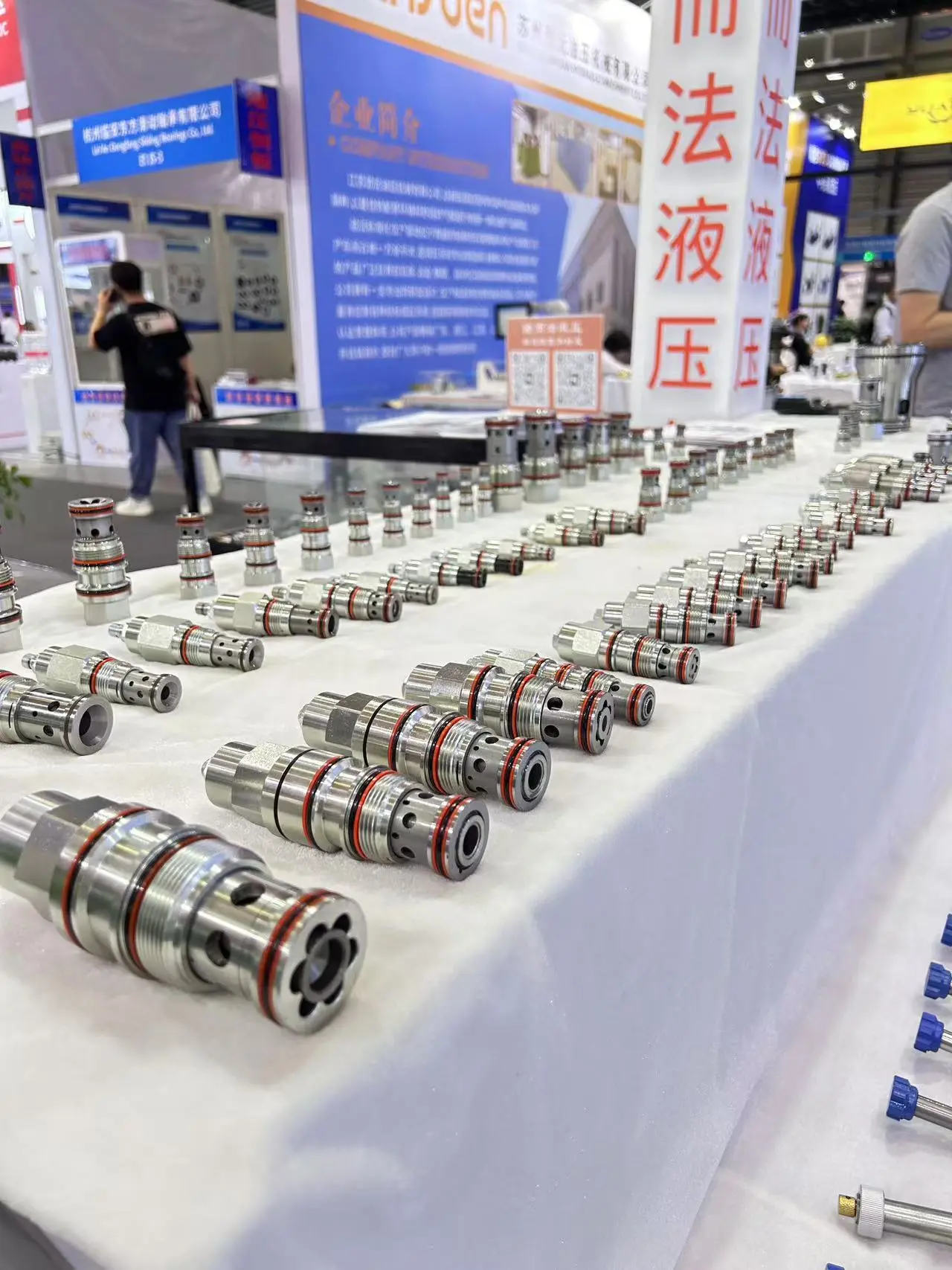

Why Longerfa Hydraulic?

Located in the industrial heart of Zhenhai District, Ningbo, Longerfa Hydraulic has built a reputation as a trusted global supplier of high-performance hydraulic cartridge valves, especially relief valves for construction machinery. Our team of engineers and technicians combines advanced technology with in-depth industry knowledge to deliver superior hydraulic solutions.

-

Global Reach: Our valves are exported to North America, Europe, Southeast Asia, and other regions, serving clients in industries including construction, mining, agriculture, and heavy equipment.

-

Tailor-Made Solutions: We provide OEM and ODM services, offering design customization, technical support, and fast delivery.

-

Stringent Quality Control: Each valve undergoes multiple stages of inspection, including 100% flow testing and pressure resistance validation before shipment.

-

Sustainable Development: Our manufacturing processes are built with environmental responsibility in mind, supporting both durability and ecological stewardship.

Final Thoughts

Hydraulic valve failures are not just mechanical inconveniences—they can cause costly downtime, safety hazards, and reputational damage. But with the right preventative measures and reliable manufacturing partners, these issues can be significantly minimized.

At Longerfa Hydraulic, we are proud to contribute to the reliability and efficiency of construction machinery around the world. By choosing quality, you’re choosing safety, performance, and long-term value.

Contact Us

To learn more about our products or request a quotation, please browse website and reach out to our international sales team.