Hydraulic Valve Maintenance Checklist for Heavy Machinery Operators

Why Hydraulic Valve Maintenance Matters

Hydraulic valves control the flow and direction of fluid within a Hydraulic System. Malfunctions in these valves can lead to severe consequences, including system overheating, erratic equipment movement, or complete machine failure. Regular inspection and preventive maintenance of hydraulic valves ensure:

-

Enhanced operational safety

-

Improved efficiency

-

Extended component lifespan

-

Minimized repair and replacement costs

At Ningbo Longerfa, we understand the high demands of the construction and industrial sectors, and we engineer our valves to meet strict performance and durability standards. Still, proactive maintenance is key to achieving the full potential of any hydraulic valve.

The Essential Hydraulic Valve Maintenance Checklist

1. Daily Visual Inspection

Before starting machinery operations each day, inspect hydraulic valves and the surrounding system for visible signs of wear or damage:

-

Look for leaks around fittings and seals.

-

Check for cracked hoses or loose connections.

-

Examine the valve body for corrosion or abrasion.

If any abnormalities are found, address them immediately to prevent more severe system issues.

2. Check Hydraulic Fluid Quality

Poor hydraulic fluid quality is a leading cause of valve malfunction. At least once a week, inspect the fluid for:

-

Color – Healthy fluid is typically amber or clear. Dark or milky fluid may indicate contamination.

-

Viscosity – Changes in viscosity can affect valve performance and responsiveness.

-

Contaminants – Look for signs of water, air bubbles, or particles.

Regularly replace or filter the fluid according to the manufacturer's guidelines.

3. Monitor System Pressure and Flow Rates

Using a pressure gauge or flow meter, check that the hydraulic system is operating within the recommended parameters. Unusual spikes or drops in pressure may indicate valve wear or Internal Leakage. This step is particularly important for components likerelief valves and directional control valves, which are critical to safe system function.

4. Inspect Valve Operation

During machine operation, pay close attention to the responsiveness and behavior of hydraulic valves:

-

Do actuators respond promptly and smoothly?

-

Are there any delays, jerky motions, or noise from the system?

-

Does the valve return to its neutral position correctly?

Erratic behavior may signal internal contamination or worn valve spools.

5. Lubricate Moving Parts

Valves with moving parts—such as spool valves or proportional control valves—require adequate lubrication to prevent friction and wear. Use only approved lubricants as specified in the valve documentation.

6. Tighten Loose Bolts and Fittings

Vibration from heavy-duty machinery can loosen bolts and fittings over time. Check all fasteners associated with hydraulic valves and tighten them to the proper torque specification. This prevents leaks and maintains structural integrity.

7. Check Electrical Connections (for Electro-Hydraulic Valves)

For systems that include electro-hydraulic valves, inspect wiring harnesses and connectors for corrosion, loose terminals, or insulation damage. Faulty connections can lead to inconsistent valve operation or failure.

Maintenance Frequency Guidelines

| Task | Frequency |

|---|---|

| Visual Inspection | Daily |

| Fluid Quality Check | Weekly |

| System Pressure Check | Weekly |

| Valve Operation Test | Weekly |

| Lubrication | Monthly |

| Electrical Inspection | Monthly |

| Full System Audit | Quarterly |

How Ningbo Longerfa Supports Long-Term Reliability

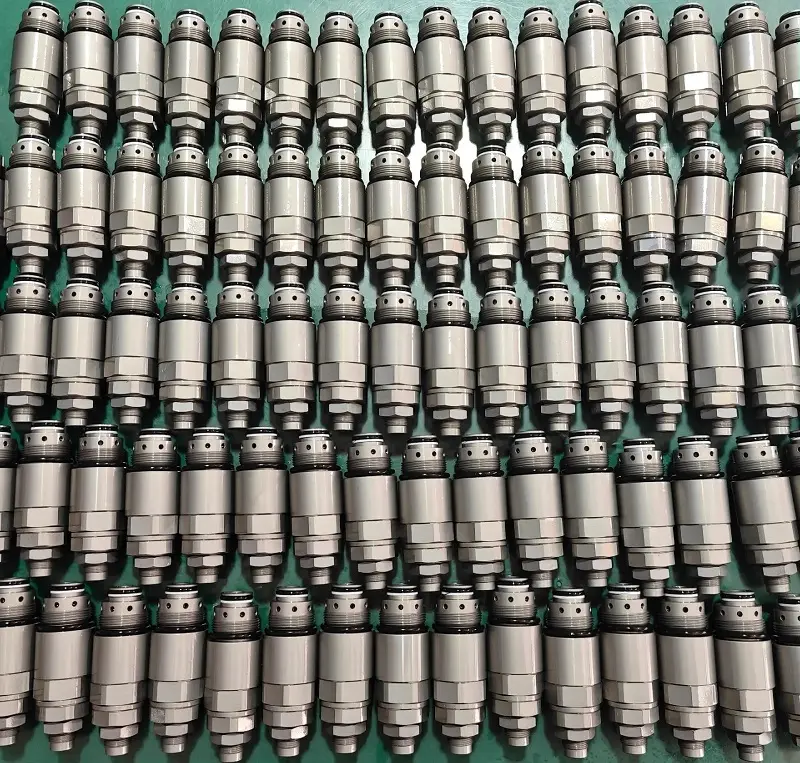

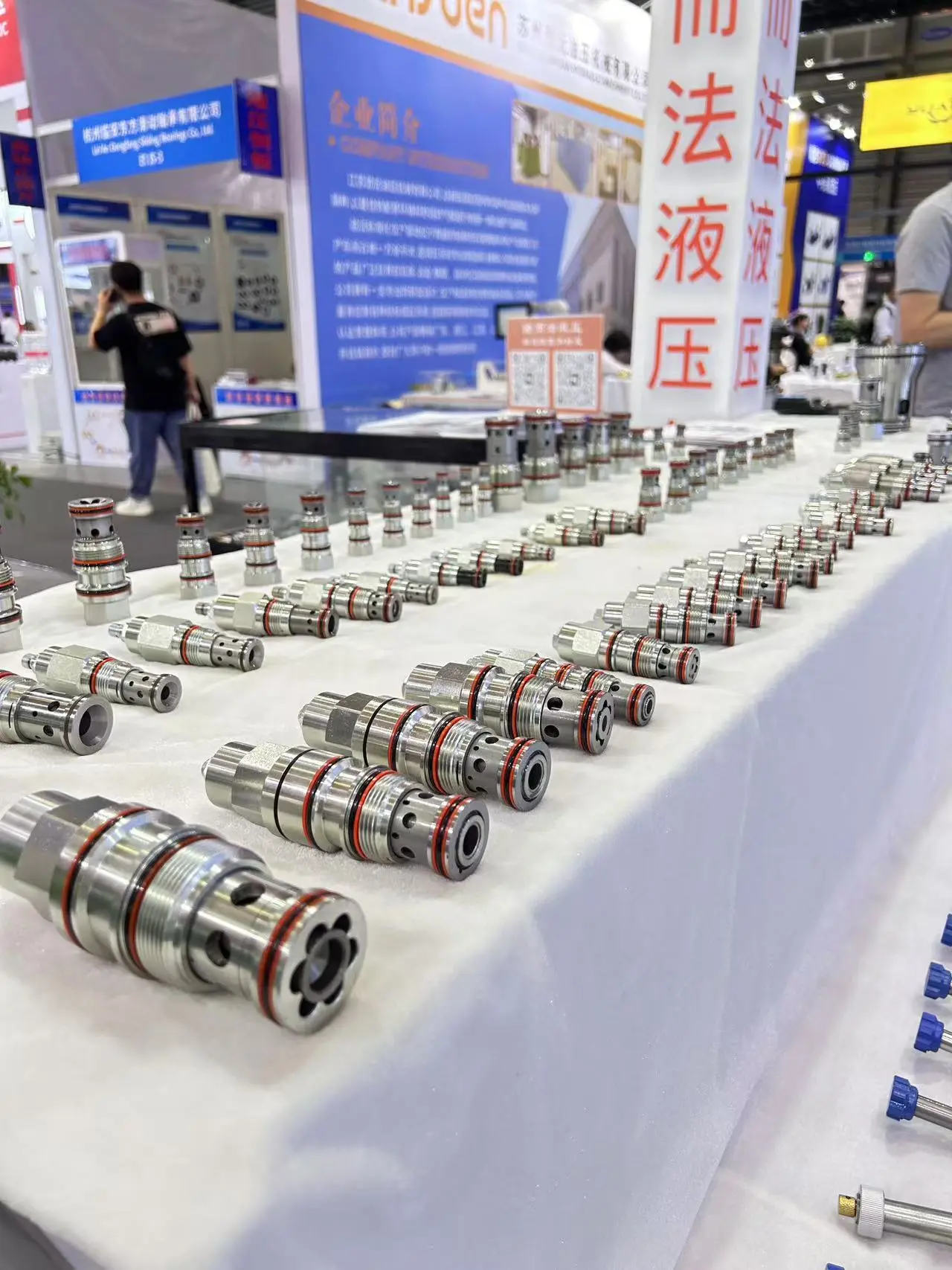

At Ningbo Longerfa Hydraulic Co., Ltd., we are committed to delivering not only high-performance valves but also the technical support that our clients need to succeed. Our valves are designed with easy maintenance in mind, using durable seals, corrosion-resistant materials, and precision-engineered components to reduce the frequency and complexity of servicing.

We also offer:

-

Custom valve solutions for specific machinery types

-

Maintenance training and documentation

-

After-sales support and spare parts supply

Whether you are operating excavators, loaders, or any other type of construction equipment, trust Ningbo Longerfa to keep your hydraulic system performing at its best.

Final Thoughts

Hydraulic valve maintenance may seem like a small task, but its impact on machine performance and safety is enormous. With a consistent checklist and a proactive approach, heavy machinery operators can extend the life of their equipment and avoid costly downtime.

For more information about our full range of hydraulic valves and services, contact Ningbo Longerfa Hydraulic Co., Ltd. today or explore our product catalog online.

Contact Us:

📧 ken@longerfa.com david@longerfa.com