Preventing Hydraulic Oil Contamination to Avoid Cartridge Valve Failure: Essential Measures for Longevity

The Impact of Hydraulic Oil Contamination on Cartridge Valves

Cartridge valves, including excavator relief valves, self-Reducing Valves, and auxiliary control valves, are precision components that rely on clean hydraulic oil for smooth operation. Contaminants such as dirt, metal particles, water, and air can cause:

-

Increased wear and tear on valve components

-

Sticking or sluggish valve response

-

Pressure fluctuations leading to system instability

-

Complete valve failure, resulting in costly downtime

To mitigate these risks, proper contamination control strategies must be implemented.

Key Prevention Measures for Hydraulic Oil Contamination

1. Use High-Quality Hydraulic Filters

Installing high-efficiency filters helps remove particulate matter before it reaches sensitive components like excavator relief valves and self-reducing valves. Regular filter replacement is crucial to maintaining system cleanliness.

2. Regular Oil Analysis and Maintenance

Periodic oil sampling and testing can detect contamination early. Implementing a scheduled oil change program prevents sludge buildup and extends the lifespan of auxiliary control valves.

3. Proper Storage and Handling of Hydraulic Fluids

Hydraulic oil should be stored in sealed, clean containers to prevent moisture and dust ingress. Contamination often occurs during refilling, so using filtered transfer pumps is recommended.

4. Seal Integrity and System Design

Worn seals and faulty breathers allow contaminants to enter the hydraulic system. Ensuring proper sealing and using desiccant breathers can significantly reduce contamination risks.

5. Educate Operators on Best Practices

Training equipment operators to recognize signs of contamination (e.g., unusual noises, erratic valve behavior) helps in early detection and prevention.

Longerfa’s High-Performance Valves for Reliable Operation

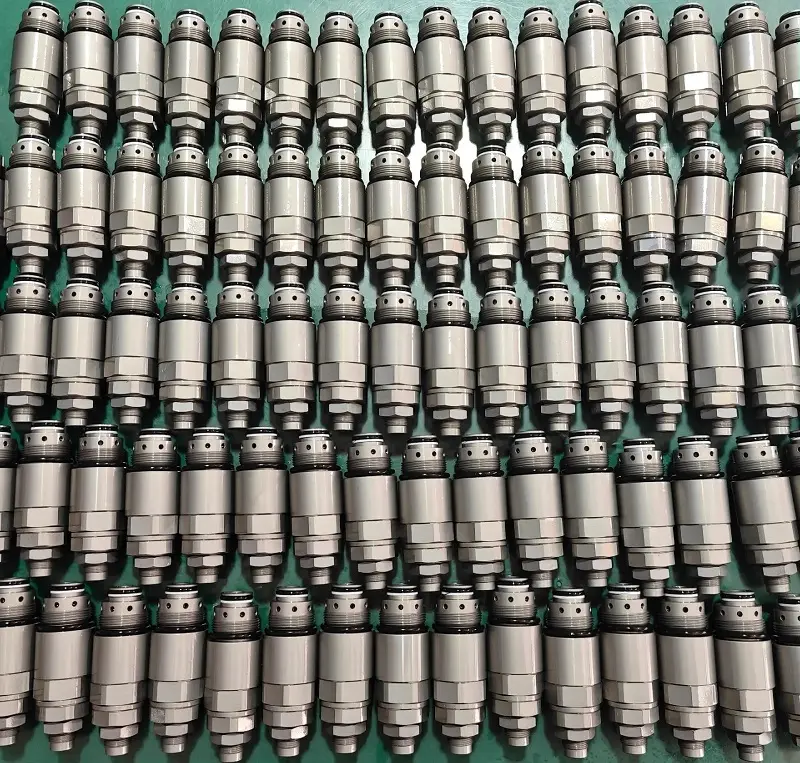

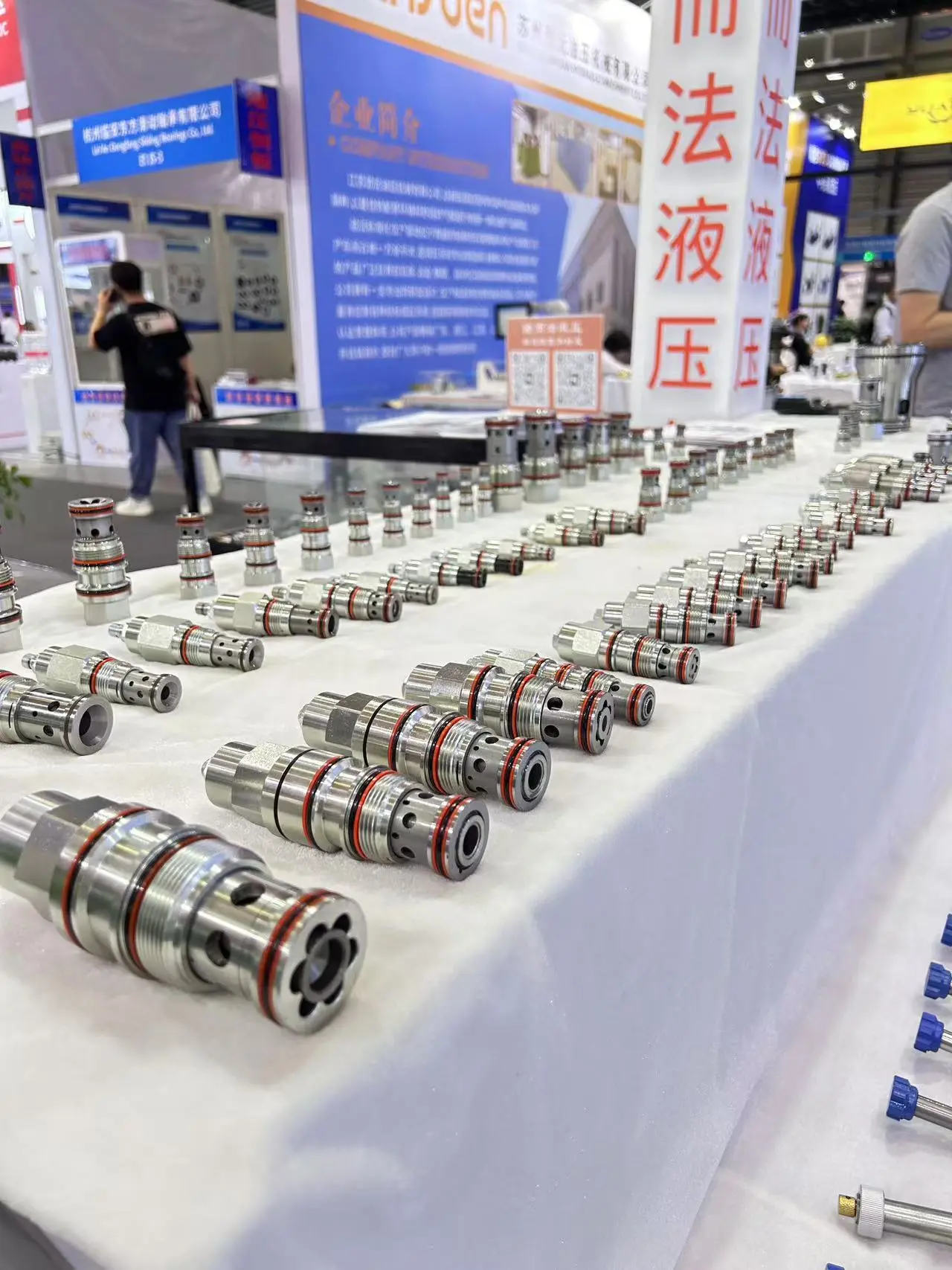

At Ningbo Longerfa Hydraulic Co., Ltd., we design and manufacture durable hydraulic valves, including:

-

Excavator Relief Valves – Ensures stable pressure control under heavy loads.

-

Self-Reducing Valves – Maintains consistent downstream pressure for precision operations.

-

Auxiliary Control Valves – Enhances machine functionality with reliable flow control.

Our products are built to withstand harsh conditions, but proper maintenance remains essential for longevity.

Conclusion

Preventing hydraulic oil contamination is critical to avoiding cartridge valve failures in excavators and industrial machinery. By adopting proactive filtration, regular maintenance, and proper handling practices, operators can ensure the reliability of excavator relief valves, self-reducing valves, and auxiliary control valves.

For premium hydraulic solutions, explore our product range at:

🔗 https://www.longerfa.com/cn/products.php

Ningbo Longerfa Hydraulic Co., Ltd. – Your trusted partner for reliable hydraulic valve solutions! 🚜🔧