The Role of Pressure Relief Valves in Construction Machinery: Enhancing Safety, Stability, and Hydraulic Efficiency

Understanding Pressure Relief Valves in Hydraulic Systems

Hydraulic Systems operate based on the transmission of fluid power under pressure. While this offers tremendous force and control, it also creates potential risk:too much pressure can damage components, cause failure, and pose safety hazards to both the machine and its operator.

Pressure relief valves (PRVs) are designed to limit the maximum pressure in a hydraulic circuit. When pressure exceeds the preset level, the valve opens to allow excess fluid to flow back into the reservoir or alternate line, thereby protecting the system. These valves ensure that machines maintain stable operation, even under heavy loads or unexpected resistance.

In construction machinery, this becomes even more critical. Excavators, for instance, encounter widely varying hydraulic demands while performing tasks such as digging, breaking, lifting, and rotating. Without a precisely calibrated pressure relief system, the entire operation becomes unstable, inefficient, and dangerous.

Main vs. Secondary Relief Valves – Key Differences

In an excavator's hydraulic system, both main and secondary relief valves are employed to control pressure, but each serves a different function:

-

Main Relief Valves are installed in the central hydraulic circuit. They govern the maximum system pressure and serve as the primary safety device. These valves must respond instantly and reliably to prevent overpressure in the entire system.

-

Secondary Relief Valves, on the other hand, are used in individual sub-circuits or specific actuators, such as boom cylinders, arm cylinders, or swing motors. These valves provide localized pressure control, safeguarding specific functions from pressure spikes or malfunctions.

At Ningbo Longerfa, we design and manufacture both types, engineered to meet the precise performance needs of different excavator models and operating conditions.

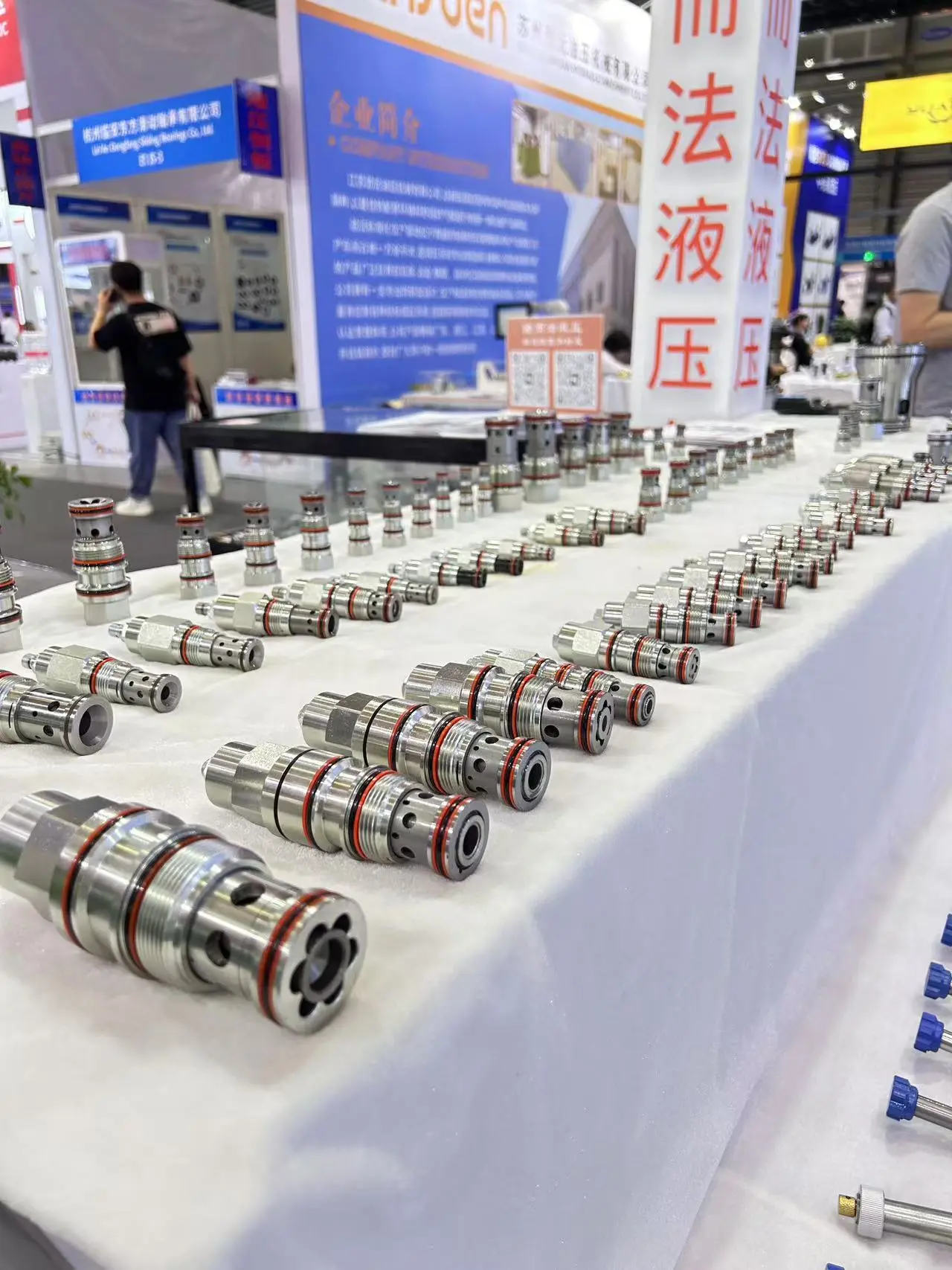

Technical Highlights of Longerfa Pressure Relief Valves

What sets Longerfa’s relief valves apart in the marketplace is a combination of precision engineering, material selection, and rigorous testing. Our valves offer:

-

High pressure stability under fluctuating loads

-

Fast response times to sudden pressure surges

-

Low internal leakage, improving system efficiency

-

Corrosion-resistant materials for long-term durability

-

Customization options to match OEM and aftermarket requirements

Each valve undergoes 100% factory testing to verify pressure settings, response sensitivity, and leakage rates. We use CNC-machined parts to ensure dimensional accuracy, and our designs follow international standards such as ISO and DIN when required.

Applications Across Global Construction Machinery

Longerfa’s relief valves are widely used in:

-

Hydraulic excavators (various tonnage models)

-

Wheel loaders and backhoe loaders

-

Mini-excavators and compact equipment

-

Crawler bulldozers and track-type machines

-

Hydraulic breakers and attachments

Our products are trusted by both OEM manufacturers and aftermarket service providers across China, Southeast Asia, South America, the Middle East, and Eastern Europe. Whether you are building new machines or maintaining an aging fleet, Longerfa provides cost-effective, high-performance hydraulic valve solutions that you can rely on.

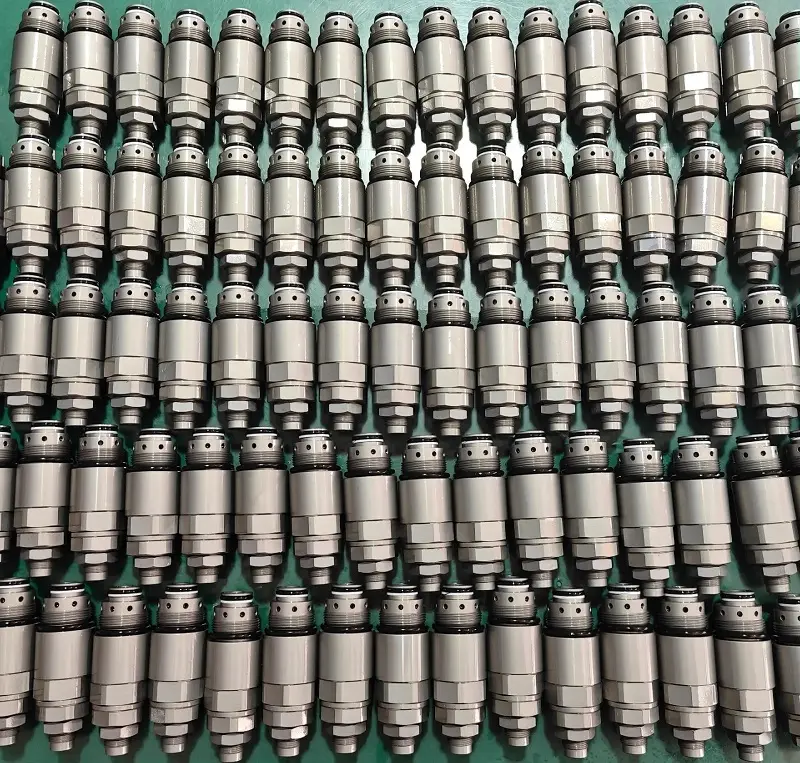

Manufacturing Strength and Quality Commitment

Headquartered in Ningbo, China, Longerfa operates a modern production facility equipped with CNC machining centers, automated assembly lines, and in-house testing labs. We have established a comprehensive quality management system, covering raw material inspection, process control, and final product evaluation.

What makes Longerfa different is our ability to provide:

-

Flexible order volumes, from small batches to mass production

-

Fast delivery times, thanks to streamlined logistics and stock management

-

Technical support and drawing customization to match client requirements

-

Multilingual service for international clients

We welcome custom development projects and offer reverse engineering for clients who need to replace or upgrade existing relief valves in their machinery.

Future Outlook: Smarter Hydraulics, Higher Demands

As construction machinery evolves with digital controls, automation, and higher power densities, the performance requirements for hydraulic components are becoming more stringent. In this landscape, pressure relief valves must be:

-

Smarter – integrating with sensors for real-time monitoring

-

More durable – to withstand higher pressures and temperature variations

-

More compact – to fit within increasingly space-constrained systems

At Ningbo Longerfa, we are actively investing in R&D and innovation, working to develop next-generation relief valves that meet the needs of intelligent, eco-friendly construction equipment.

Conclusion

In the grand scheme of construction machinery, pressure relief valves may seem like small components, but their impact on performance, safety, and system longevity is immense. As machines become more powerful and hydraulic systems more complex, choosing the right valve partner is more important than ever.

Ningbo Longerfa is proud to support this industry with reliable, affordable, and technically advanced relief valves. We invite equipment manufacturers, distributors, and repair centers to connect with us and explore our full range of hydraulic valve solutions.

Contact us today to discuss your needs, request a sample, or learn more about how we can help power the next generation of construction machinery.