Troubleshooting Hydraulic Control Valve Failures in Lifting Equipment

Why Hydraulic Control Valves Matter

Hydraulic Control valves regulate the flow and direction of hydraulic fluid in a system. In lifting equipment, they directly affect load handling, movement precision, and safety. Any malfunction can causeloss of lifting power, uncontrolled descent, jerky movement, or even complete system failure, posing risks to both operations and personnel.

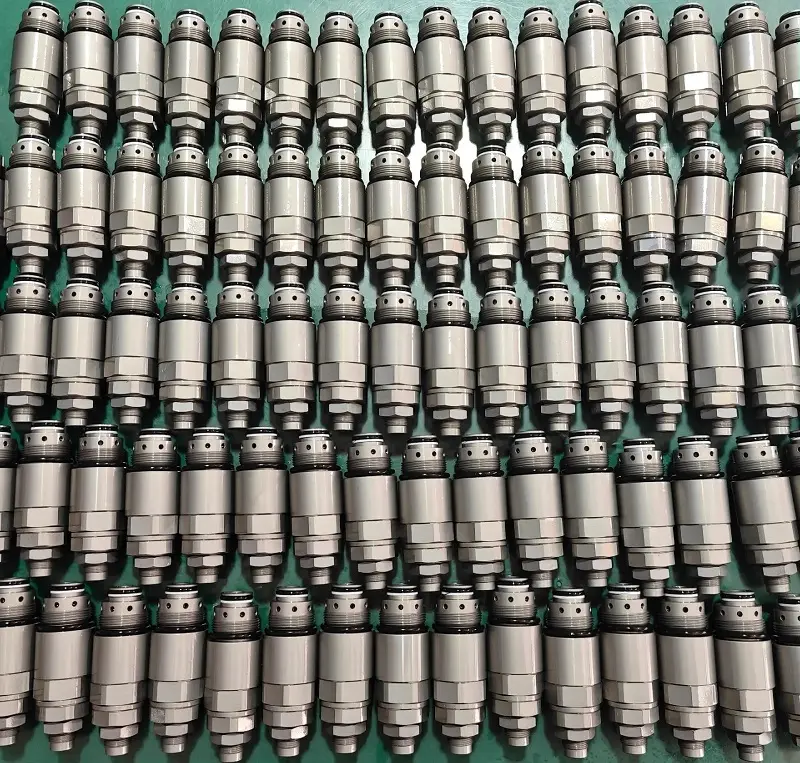

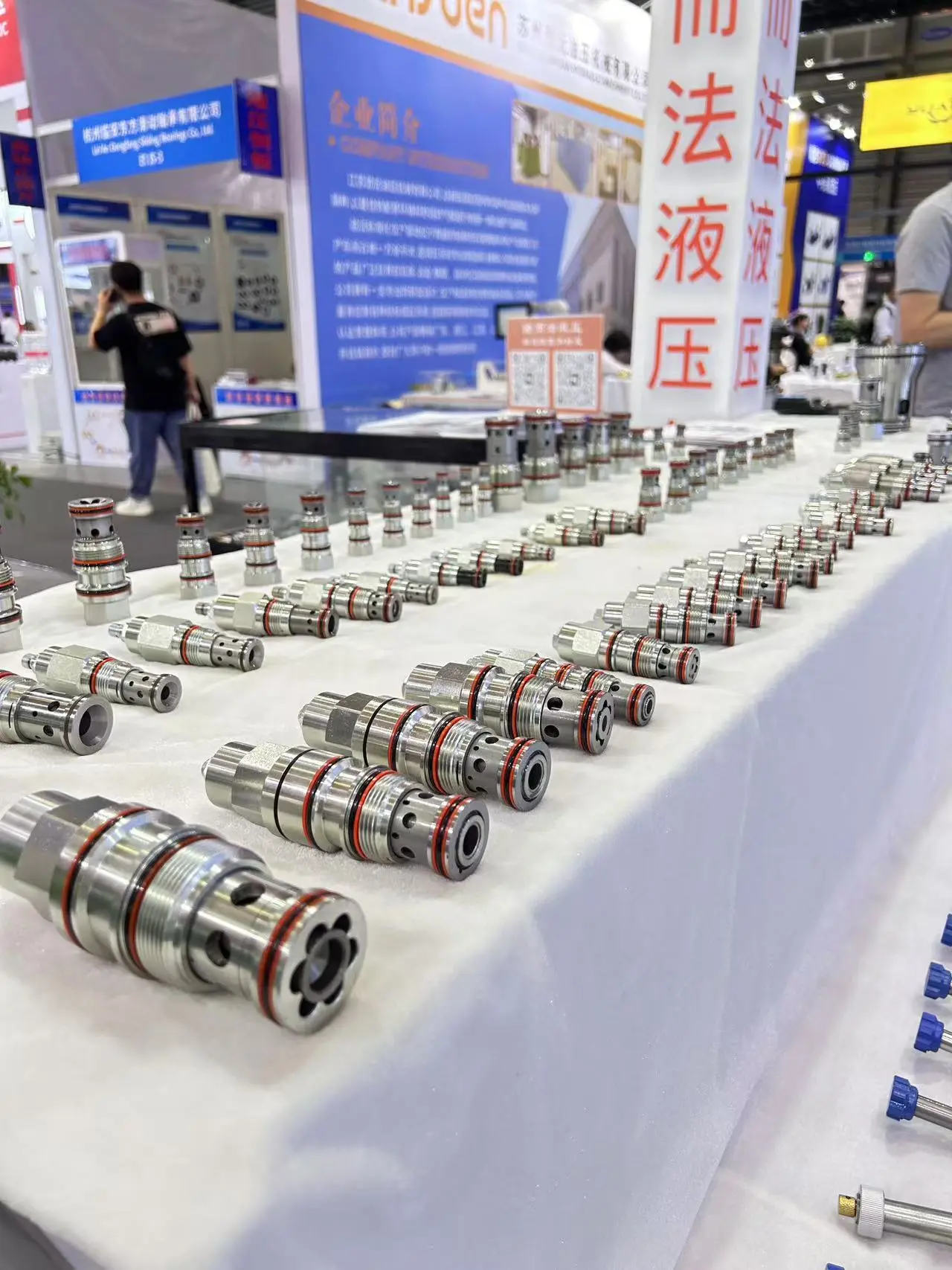

Our threaded Cartridge Valves are designed for durability and precision, but like any mechanical system, even the best components can be compromised by environmental conditions, poor maintenance, or improper installation.

Common Symptoms of Valve Failures

Operators and maintenance teams should stay alert to early warning signs of valve-related issues. Here are some key symptoms:

-

Sluggish or delayed response when activating the lift

-

Inconsistent lifting speed or pressure fluctuations

-

Unusual noises such as hissing or knocking

-

Drifting or sagging loads when stationary

-

Complete loss of function in one or more hydraulic movements

Recognizing these signs early allows for timely intervention and prevents costly downtime.

Top Causes of Hydraulic Control Valve Failures

Through years of field data, customer feedback, and in-house testing, Ningbo Longerfa has identified the following leading causes of hydraulic valve failures:

1. Contamination in the Hydraulic Fluid

Dirt, metal shavings, or degraded seal material can enter the fluid, clogging valve orifices or causing internal damage. Contaminants can scratch valve seats, affect spool movement, and eventually lead to internal leakage.

Solution: Implement high-quality filtration systems and follow a strict fluid maintenance schedule. Replace filters regularly and use only clean, recommended hydraulic oils.

2. Improper Installation or Torqueing

Threaded cartridge valves must be installed to manufacturer specifications. Over- or under-tightening can cause seal deformation, internal stress, or misalignment of the valve components.

Solution: Use calibrated torque tools during installation and refer to technical documentation provided by Longerfa. Our cartridge valves come with detailed assembly instructions to assist your technicians.

3. Seal Wear or Failure

Seals play a critical role in preventing internal and external leaks. With time, they degrade due to pressure cycles, heat, or chemical breakdown of materials.

Solution: Periodic inspection and proactive seal replacement can prevent major failures. At Longerfa, we offer high-performance sealing materials for extended durability under harsh working conditions.

4. System Overpressure

When operating pressures exceed valve design limits, it can cause cracks, spool deformation, or immediate valve failure. Overpressure might be caused by malfunctioning relief valves or blocked actuators.

Solution: Ensure proper pressure regulation using pressure relief valves and monitoring gauges. Select valves that match the pressure specifications of your system.

5. Corrosion and Environmental Exposure

In outdoor or marine environments, moisture and temperature swings can lead to rust, oxidation, and eventual binding of valve components.

Solution: Choose corrosion-resistant materials or coated valves when operating in extreme environments. Longerfa provides customizable material options, including stainless steel, to match application demands.

Step-by-Step Troubleshooting Guide

At Longerfa, we recommend a structured approach when troubleshooting valve failures:

-

Visual Inspection

-

Check for leaks, damaged hoses, or cracked housings.

-

Examine valve mounting and electrical connections.

-

-

Check Hydraulic Fluid

-

Test fluid cleanliness, viscosity, and temperature.

-

Look for signs of emulsification (water contamination).

-

-

Pressure Testing

-

Use a pressure gauge to verify inlet and outlet pressures.

-

Compare with system design specs.

-

-

Function Testing

-

Activate the control circuit and observe spool response.

-

Check solenoids or pilot signals if electronically controlled.

-

-

Valve Disassembly and Cleaning

-

Remove and clean the valve in a contamination-free environment.

-

Inspect all internal components for wear, damage, or blockage.

-

-

Replace or Recalibrate

-

If damage is irreparable, replace the valve with a certified Longerfa replacement.

-

Recalibrate system parameters as necessary.

-

Longerfa's Commitment to Quality and Support

Every valve that leaves our Ningbo-based factory is engineered and tested to meet stringent international standards. Whether you're working with our standard valve catalog or a customized manifold solution, our priority is long-term reliability in demanding hydraulic systems.

To support our global partners, we provide:

-

Comprehensive technical documentation and CAD models

-

On-site or remote engineering support

-

Fast response on spare parts and replacements

-

Customized design services for OEMs

Looking Ahead: Smart Diagnostics and Predictive Maintenance

With the rise of Industry 4.0, smart sensors and IoT-enabled diagnostics are becoming increasingly available for hydraulic systems. Longerfa is actively researching and developing integrated valve technologies that allow real-time condition monitoring, helping users to predict failures before they occur.

Final Thoughts

Hydraulic control valve failures in lifting equipment are not just a maintenance concern—they’re an operational risk. By understanding the causes, symptoms, and solutions, operators and technicians can extend equipment lifespan, improve safety, and reduce costly downtime.

At Ningbo Longerfa Hydraulic Co., Ltd., we are more than just a valve manufacturer—we are your partner in hydraulic control excellence. From standard cartridge valves to fully engineered hydraulic manifolds, we are committed to keeping your lifting equipment operating at peak performance.

For more information or to consult with our engineering team, please visit:

🌐 www.longerfa.com

📧 Email: ken@longerfa.com