Why Pilot Operated Check Valves Always Matter

Industrial systems rely on precision and safety to function effectively. A Pilot Operated check valve plays a vital role in achieving this by controlling flow and preventing reverse flow. These valves ensure system safety and reliability, making them indispensable in various industries.

The growing demand for these valves underscores their importance:

- The global pilot operated safety valve market is expected to grow from USD 1.2 billion in 2023 to USD 2.3 billion by 2032, with a CAGR of 7.2%.

- Increasing industrialization and strict safety regulations drive this growth, highlighting their necessity in maintaining safety standards.

Their unique design enhances efficiency and precision, making them a cornerstone of modern industrial systems.

Key Takeaways

- Pilot-operated check valves manage fluid flow and stop backflow. They keep systems safe and working well.

- These valves are very important in industries like oil and gas. They help keep pressure steady and protect equipment from harm.

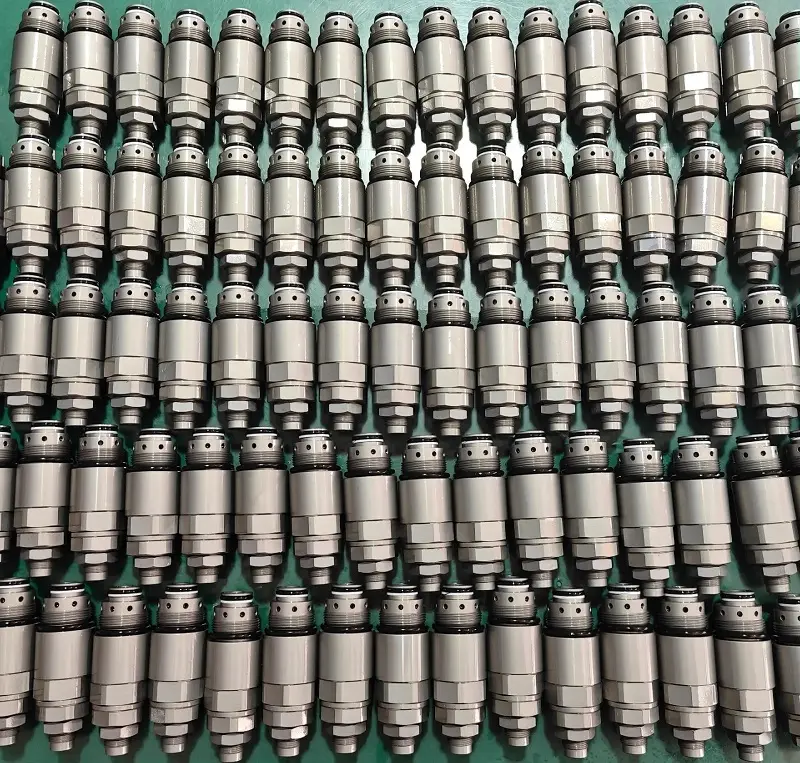

- Taking care of these valves and using good parts is key. This stops leaks and keeps the valves working their best.

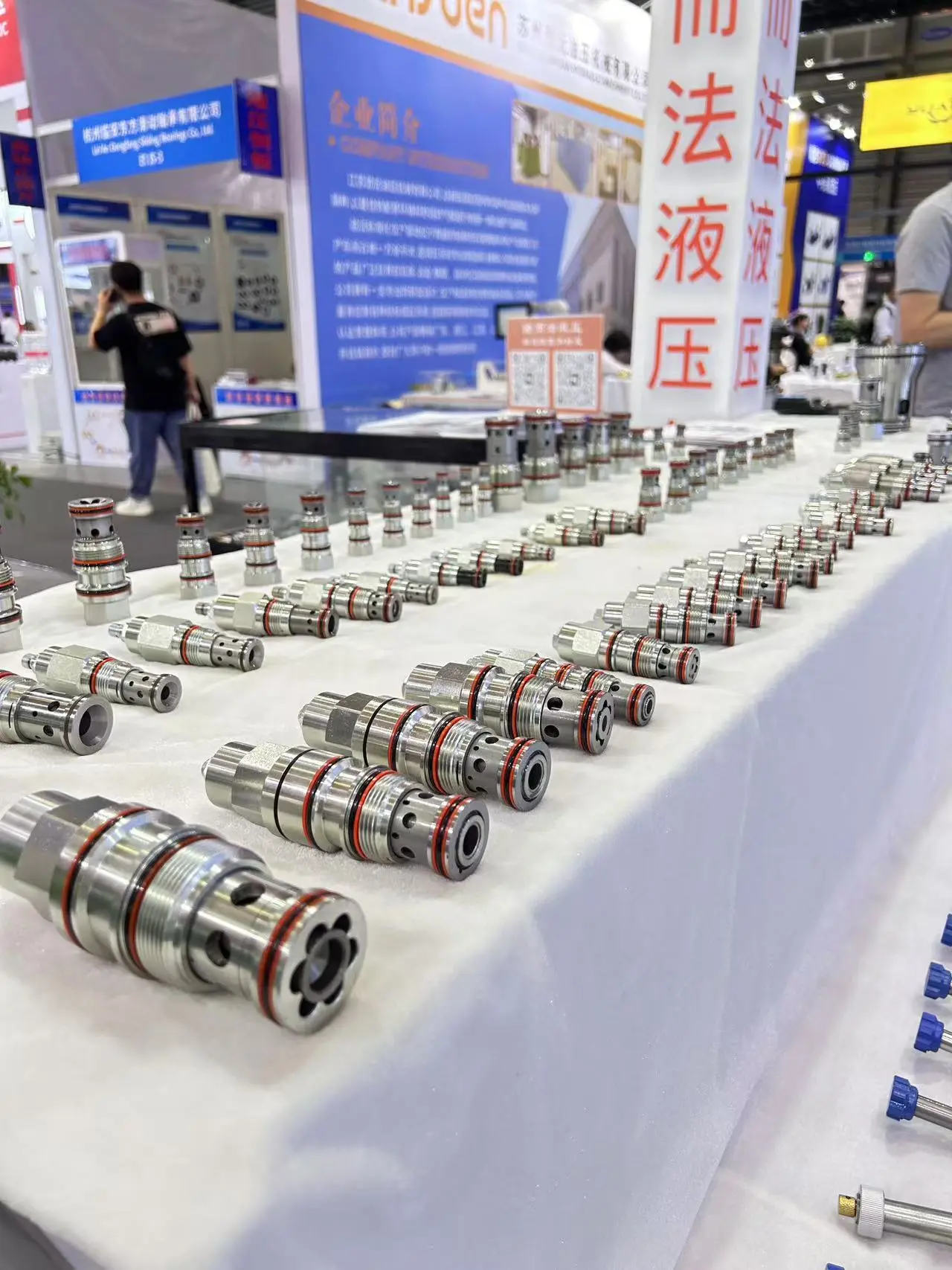

- More people are using these valves now, showing how useful they are in many industries.

- Knowing how hydraulic and pneumatic systems differ helps pick the right valve for each job.

Overview of Pilot-Operated Check Valves

What Are Pilot-Operated Check Valves?

Definition and primary function

A pilot-operated check valve is a specialized device designed to control fluid flow in industrial systems. Its primary function is to allow fluid to flow in one direction while preventing reverse flow. Unlike standard check valves, it uses a pilot signal to override the check mechanism, enabling controlled reverse flow when necessary. This feature makes it highly versatile in applications requiring precise flow control and system safety.

The valve operates by sensing system pressure through a pilot mechanism. When the pilot signal activates, it adjusts the closing force on the main valve disc, allowing fluid to flow in the reverse direction. This design ensures efficient pressure management and prevents system failures caused by backflow.

Key differences from standard check valves

Pilot-operated check valves differ significantly from standard check valves. While standard check valves rely solely on system pressure to open or close, pilot-operated versions use an external pilot signal for added control. This allows them to handle higher pressures and provide greater operational flexibility.

Additionally, pilot-operated check valves offer advanced features like modulating action, which enables controlled Pressure Relief based on system conditions. Standard check valves lack this level of precision, making them less suitable for complex industrial systems.

Why Are They Important?

Role in maintaining system integrity

Pilot-operated check valves play a critical role in maintaining system integrity. They prevent backflow, which can damage equipment and compromise safety. For example, these valves protect emergency pumps from reverse flow during downtime, ensuring the hydraulic system remains pressurized and operational.

Their ability to block contaminants from entering the system further enhances reliability. By maintaining clean and stable operations, these valves reduce the risk of catastrophic failures in high-stakes industries like oil and gas or power generation.

Advantages over traditional valves

The advantages of pilot-operated check valves over traditional valves are numerous. First, they achieve seat tightness up to 98% of set pressure, ensuring zero leakage during normal operations. Second, their design allows them to operate efficiently under high-pressure conditions, making them ideal for industries requiring precise pressure management.

Moreover, innovations in valve design, such as IoT integration and predictive maintenance features, have enhanced their efficiency and reliability. These advancements make pilot-operated check valves indispensable in modern industrial systems.

Working Principle

Pneumatic Control Mechanism

How air pressure operates the valve

I find the pneumatic control mechanism of a pilot operated check valve fascinating. It uses air pressure to control the valve's operation. When air pressure is applied to the pilot port, it overrides the check mechanism. This action allows fluid to flow in the reverse direction. Without the pilot signal, the valve remains closed, preventing backflow. This design ensures precise control over fluid movement, even in high-pressure systems.

The system's efficiency comes from its simplicity. For example, backpressure sensing indicates the cylinder's position without needing additional limit valves. As the cylinder retracts, it creates backpressure behind the piston. By restricting exhaust air at the control valve, the system increases pressure and slows the cylinder rod's return. This process enhances control and reduces wear on components.

Components involved in pneumatic control

The pneumatic control mechanism relies on several key components. These include the pilot port, main valve disc, and sealing elements. Each part plays a critical role in ensuring smooth operation. The pilot port receives the air signal, which activates the mechanism. The main valve disc adjusts its position based on the pilot signal, allowing or blocking fluid flow. Sealing elements prevent leaks, maintaining system integrity.

The design of these components offers several advantages, as shown in the table below:

| Advantage | Modular System Benefits | Comparison to Other Systems |

|---|---|---|

| Proven, reliable design | Yes | N/A |

| Lower component costs | Yes | N/A |

| Simple plumbing and troubleshooting | Yes | N/A |

| Lower air consumption | Yes | N/A |

| No air locks | Yes | N/A |

| Smaller total package | Yes | N/A |

| Explosion-proof system | Yes | Compared to electrical-relay control |

| Lower power consumption | Yes | Compared to electrical-relay control |

| Eliminates solenoids and relays | Yes | Compared to electrical-relay control |

| Single air supply | Yes | Compared to electrical-relay control |

| No heat buildup | Yes | Compared to electrical-relay control |

Reverse Flow Mechanism

How reverse flow is enabled with a pilot signal

Reverse flow becomes possible when the pilot signal activates. The signal reduces the closing force on the main valve disc. This action allows fluid to flow in the opposite direction. I’ve observed that this feature is particularly useful in systems requiring controlled backflow. It ensures that reverse flow occurs only when necessary, maintaining system safety and efficiency.

Scenarios where reverse flow is necessary

Reverse flow is essential in many industrial applications. For instance, it allows hydraulic cylinders to retract smoothly. It also helps in systems where fluid needs to return to a reservoir for recirculation. In emergency situations, reverse flow can prevent system damage by relieving excess pressure. These scenarios highlight the versatility of the pilot operated check valve in managing complex fluid dynamics.

Mechanical Analysis of Pneumatic Control Systems

Force Dynamics in Pilot-Operated Check Valves

Interaction between pilot pressure and valve components

I find the interaction between pilot pressure and valve components fascinating. It demonstrates how precision engineering ensures smooth operation. As inlet pressure rises, the pilot piston seals off the main valve inlet pressure from the dome pressure. At the same time, it vents the dome pressure to the modulator piston. This creates a net upward force on the modulator piston due to the differential area. As the inlet pressure continues to increase, the main valve opens fully, achieving full lift. This dynamic relationship between pilot pressure and valve operation highlights the importance of force balance in maintaining system efficiency.

To visualize this, I often refer to diagrams that illustrate the process. For example:

| Figure | Description |

|---|---|

| 6 | Shows system pressure from the main valve inlet fed to the dome area by the pilot through interconnected tubing, equalizing pressure on the disc. |

| 7 | Depicts the pilot piston sealing off the main valve inlet pressure and relieving dome pressure, resulting in a net upward force on the modulator piston. |

| 8 | Demonstrates the main valve fully open as inlet pressure increases, allowing for full lift and capacity within 10% of set pressure. |

These figures help me understand how the Pilot Operated Check Valve achieves precise control under varying conditions.

Impact of system pressure on valve performance

System pressure plays a critical role in valve performance. High pressures can enhance the valve's ability to maintain flow control, but they also demand robust components to withstand the stress. I’ve noticed that fluctuations in system pressure can affect the valve's responsiveness. Consistent pressure ensures smooth operation, while sudden changes may disrupt the balance of forces within the valve. This underscores the need for reliable pressure management in pneumatic systems.

Common Challenges in Pneumatic Systems

Seal wear and tear

Seal wear is one of the most common issues I encounter in pneumatic systems. Maintaining proper tolerances in seals is crucial to prevent air leakage. Even minor degradation can lead to reduced performance and increased energy consumption. Regular inspections help identify early signs of wear, allowing for timely replacement. Keeping detailed maintenance logs also helps track recurring issues and ensures the system remains efficient.

Pressure fluctuations and their effects

Pressure fluctuations can destabilize pneumatic systems. I’ve seen how sudden changes in pressure can cause components to wear out faster or lead to erratic system behavior. Effective control mechanisms, such as pressure regulators, help mitigate these fluctuations. By stabilizing the system, they reduce the risk of damage and improve overall reliability. Accurate documentation of performance logs further aids in identifying patterns and addressing these challenges proactively.

Industrial Applications

Common Use Cases

Applications in pneumatic systems

I’ve seen pilot-operated check valves excel in pneumatic systems. These systems often require precise control of air pressure to operate machinery or tools. For example, in automated manufacturing lines, these valves ensure air flows in the correct direction, preventing disruptions. They also allow controlled reverse flow when needed, such as during the retraction of pneumatic cylinders. This feature improves the efficiency of operations and reduces wear on components.

Another common use is in material handling systems. Here, the valves maintain consistent air pressure to lift and move heavy loads. Their ability to handle high-pressure conditions makes them indispensable in these demanding environments.

Applications in hydraulic systems

Hydraulic systems also benefit greatly from pilot-operated check valves. I’ve noticed their frequent use in construction equipment like excavators and cranes. These machines rely on hydraulic systems to lift and move heavy objects. The valves prevent backflow, ensuring the hydraulic cylinders maintain their position under load.

In industrial presses, these valves play a critical role in maintaining consistent pressure. This ensures the press operates smoothly and safely. Their ability to handle high-pressure fluids makes them ideal for hydraulic systems in industries like automotive manufacturing and metalworking.

Benefits in Industrial Systems

Enhancing system efficiency

Pilot-operated check valves significantly enhance system efficiency. They maintain fluid flow in one direction, preventing backflow and ensuring smooth operation. I’ve observed how this reduces downtime and improves operational control. Industries like oil and gas and chemical processing rely on these valves for precise fluid dynamics. Their integration into systems ensures consistent performance, even under high-pressure conditions.

Improving safety and reliability

Safety and reliability are critical in industrial systems. These valves contribute by preventing reverse flow, which could damage equipment or compromise safety. For instance, in emergency situations, they block contaminants from entering the system, maintaining clean operations. Their robust design ensures they perform reliably, even in harsh conditions. This makes them a trusted choice for industries prioritizing safety and long-term reliability.

Warning Signs of Valve Seal Failure

Identifying Seal Issues

Leakage during operation

I’ve noticed that leakage during operation is one of the most common signs of valve seal failure. When seals degrade, they lose their ability to maintain a tight closure. This allows fluid or air to escape, which can disrupt system performance. For example, in pneumatic systems, even a small leak can reduce efficiency and increase energy consumption. I always recommend checking for visible signs of leakage, such as fluid pooling around the valve or hissing sounds in air systems. These indicators often point to worn or damaged seals that need immediate attention.

Reduced system pressure

Another clear warning sign is a drop in system pressure. I’ve observed that when seals fail, they allow pressure to escape, which compromises the system's ability to function effectively. This issue often manifests as slower operation of machinery or inconsistent performance. Monitoring pressure gauges regularly can help identify this problem early. If the system struggles to maintain its usual pressure levels, it’s a strong indication that the valve seals require inspection or replacement.

Preventative Maintenance Tips

Regular inspection schedules

I’ve found that regular inspections are the best way to prevent seal failure. Routine checks help identify potential issues before they escalate. For instance:

- Regular cleaning and lubrication keep seals in good condition and extend their lifespan.

- Predictive maintenance uses data to detect early signs of wear, allowing for timely repairs.

- Scheduled inspections ensure that minor problems, like small leaks, don’t turn into costly failures.

By sticking to a consistent maintenance schedule, I’ve seen systems operate more efficiently and avoid unexpected downtime.

Choosing high-quality valve components

Using high-quality valve components is another critical step in preventing seal failure. I’ve learned that premium materials offer better durability and reliability. For example:

- High-quality seals withstand higher pressures and temperatures, reducing the risk of failure.

- Investing in robust components minimizes the need for frequent replacements, saving time and money.

- Routine cleaning and lubrication of these components further enhance their performance and longevity.

In my experience, combining regular maintenance with top-tier components ensures valves perform optimally and last longer.

Hydraulic vs. Pneumatic Applications

Key Differences in System Requirements

Pressure and flow characteristics

I’ve noticed that hydraulic and pneumatic systems differ significantly in their pressure and flow characteristics. Hydraulic systems operate at much higher pressures, ranging from 1,000 to 10,000 psi, while pneumatic systems typically function between 80 and 150 psi. This difference makes hydraulics ideal for applications requiring immense force, such as lifting heavy machinery. Pneumatics, on the other hand, excel in speed and are better suited for lighter tasks like powering air tools.

Here’s a quick comparison of their characteristics:

| Characteristic | Pneumatic Systems | Hydraulic Systems |

|---|---|---|

| Operating Pressure | 80 to 150 psi (5.5 to 10.3 bar) | 1,000 to 10,000 psi (69 to 689 bar) |

| Force Output | Lower, typically 25 times less than hydraulic | Higher, capable of generating significantly more force |

| Speed | Up to 100 inches per second | 4 to 20 inches per second |

| Precision | Accuracy tolerance of about 0.1 inches | Accuracy tolerance of 0.001 inches or better |

This table highlights how each system meets different operational needs. I’ve found that understanding these differences helps in selecting the right system for specific tasks.

Cost and maintenance considerations

Cost and maintenance also vary between these systems. Pneumatic systems are generally more affordable upfront and require less maintenance. Their components are simpler, and air leaks are less damaging than hydraulic fluid leaks. However, hydraulic systems, while more expensive, offer better durability and efficiency for high-force applications. I’ve seen industries weigh these factors carefully, especially when long-term reliability is a priority.

Selection Guide for Industrial Use

Factors to consider when choosing between hydraulic and pneumatic systems

When selecting between hydraulic and pneumatic systems, I always consider the application’s specific requirements. For high-force tasks, such as operating heavy machinery, hydraulic systems are the clear choice. Pneumatic systems, however, are better for high-speed operations or environments where cleanliness is critical. Precision also plays a role. Hydraulic systems provide greater control, making them suitable for tasks requiring fine adjustments.

Here’s a comparison to guide the decision-making process:

| Factor | Hydraulic Systems | Pneumatic Systems |

|---|---|---|

| Required Force | Better for high force applications | Suitable for low to moderate force |

| Speed | Generally slower than pneumatic | Advantageous for high-speed operations |

| Precision | Offers greater precision and control | Less precise compared to hydraulic |

| Environmental Impact | Requires measures to prevent leaks | Cleaner, ideal for sensitive environments |

This table simplifies the selection process by matching system capabilities to industrial needs.

Examples of industry-specific applications

I’ve seen hydraulic systems dominate industries like construction and manufacturing. For example, excavators and industrial presses rely on hydraulics for their immense force and precision. Pneumatic systems, on the other hand, are common in food processing and packaging, where cleanliness and speed are essential. Each system has its strengths, and understanding these applications ensures optimal performance in any industry.

Pilot-operated check valves remain essential in modern industrial systems. They ensure precise flow control and prevent reverse flow, which enhances both efficiency and safety. Their design supports operational reliability by managing pressure with precision. These valves also prevent overpressure situations, a critical safety feature in industries like power generation and chemical processing.

- They enhance system reliability through precise pressure management.

- They prevent overpressure, reducing risks in high-stakes environments.

- The market growth from USD 1.2 billion in 2023 to USD 2.3 billion by 2032 reflects their increasing demand.

Understanding how these valves work and their applications helps industries optimize operations and reduce risks effectively.

FAQ

What makes pilot-operated check valves different from standard check valves?

Pilot-operated check valves use a pilot signal to control reverse flow. Standard check valves rely only on system pressure. This added control makes pilot-operated valves more versatile and precise for industrial applications.

How do I know if my valve seals are failing?

I look for signs like leakage, reduced system pressure, or inconsistent performance. For example, fluid pooling around the valve or hissing sounds in pneumatic systems often indicate seal issues.

Can pilot-operated check valves handle high-pressure systems?

Yes, they are designed for high-pressure environments. Their robust construction and precise control mechanisms make them ideal for industries like oil and gas, where pressure management is critical.

Why is regular maintenance important for these valves?

Regular maintenance prevents issues like seal wear and pressure fluctuations. I recommend routine inspections and using high-quality components to ensure optimal performance and avoid costly downtime.

Are pilot-operated check valves suitable for both hydraulic and pneumatic systems?

Absolutely! These valves work well in both systems. Hydraulic systems benefit from their high-pressure capabilities, while pneumatic systems use their precise air control for efficient operations.